You snorting the coating again, Gunslick?????

|

|

|

You snorting the coating again, Gunslick?????

Hooroo.

Regards, Trevor.

Australia

You got to have proper ventilation...

Just spent 45 mins removing 80% of the lube grove out of my lee 6 cav mold. simple job, drilled it out till most of it was gone and a quick lap with some 800 wet/dry carborundum paper. the groove is still there, JUST as in .002 thou approx.

Cast about 50 just now and what a difference it made! you open the mold with a snap motion and all 6 just fall into the water quench.

Trouble is now its that fast to cast with, that its easy to turn out frosted boolits. No more smacking the handles/fingers etc. No more jarring sprue plates loose.

Next time I buy a mihec mold I will ask for no lube grove. Will make it easier to cast and probably easier to make.

If Trev and I make the meet this Friday I will show him the frosted ones, I am wondering if the frosting would actually add to the adhesion of the coating to the projectile. Lets face it shiney means smooth and smooth means very little purchase on the surface.

Maybe Joe can step in and give his opinion on this.

Don't worry about life, no-one gets out alive.

If any off you want to drill your lube grooves out of the mold let me give you a heads up.

Drop a small steel ball bearing in each cavity first, it will stop you accidently going too deep with the drill bit.

Slot a small wooden dowl and slide the 600 grit paper into the groove doubled over, about 2-3" in length.

Leave the ball bearing in the bottom again, to protect the tip of the mold. spin the dowel and paper in each cavity for a few seconds, all you are looking for is to round off the lube groove that's left .

You could remove it all together, but unessesary to go that far, I took the time to remove it totally from one hole, but the other 5 with the tiny reminant of the groove drop the casts clean and quickly as the one with zero lube groove.

For all those hours spent beating on the mold with a chunk of wood, well its now a thing of the past for me.

Flicking the mold open one handed is enough to drop all 6 into the water quench 99.999999999999% of the time, so much so that I don't even put the laddle down anymore. (yes I laddle pour!).

Don't worry about life, no-one gets out alive.

grem. I'm going to do that. but I'm going to use a 8mm ball nose end mill and a milling machine.

Hooroo.

Regards, Trevor.

Australia

Well after a week of reading all 1753 posts, I think I have more questions than before I started reading.

Most of my high volume casting reloading is for 32, 9mm & 38/357 in handguns. Where possible I have been using TL moulds and lube and have even managed to get the 9mm to work with TL & alox. All these loads are below 1000fps.

From reading the whole thread I get the impression I wouldn't have any trouble with simply switching to hi tek with any of these loads once I got the coating and baking sorted. I might even be able to push velocity a little higher.

Any of the colours and the standard cat would work but blue/green is probably easiest to begin with.

Have I got this right?

Does anyone shoot their TL designs coated with the blue/green unsized.

I currently don't size my alox coated TL boolits. I can't see coating being quicker than TL but I could live with that considering the other benefits and the pretty boolits but if sizing is a must then it might be the deal breaker.

I also load some reduced loads in rifles for small game hunting. 115gr in 30/30 @ 1400fps, 44gr in 222 @ 1900fps. These loads are with gas check and conventional lube. I'm of the understanding that the best colour for these would be one of the metalics, probably gold or copper/red with the extreme cat.

The same would hold true for the 45/70 and 357mag in rifle with loads in the 1300-1800fps range

Have I got this right?

Now it appears that fitting GC prior to coating is the best option but with sizing prior to coating causing bonding issues how is everyone attaching GC, over size size dies?

Finally form reading it appears the metalics add about 1 thou to diameter per coat, is this correct?

If so is anyone using it to increase diameter of boolits from moulds that drop undersize. What success have you had?

Would it be possible to increase the diameter of a 9mm design that drops 356 to 358 or 359 for use in 38/357 with 3 or 4 coats?

HITEK works on TL bullets. no issues.

Any colour is easy to use. The Blue/green doesn't have any solids, so it is easier for the nooby not to stuff it up.

If your gun like unsized bullets, go for it.

Any coating will work without GC at those velocities. We have been doing just that for years here in OZ.

Trying to use the coating to bump up the bullet size doesn't work too well. I have used it on an undersized 45 Lyman mold at low velocity, But the results were hit and miss.

Hooroo.

Regards, Trevor.

Australia

I think most of us have concluded that 2 coats is more than enough for pistol boolits

Yeah, you are over thinking itI typically equate 100 124 gr. 9mm's with 75 or 80 230 gr .45's (i.e. they require the same amount of HI-TEK/Piglet/Klass Kote/whatever). I'll need to check my notes at home to tell you how much for that amount of lead, though.

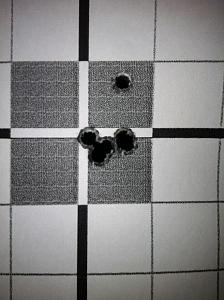

Range update. Made some 38specials today for a customer. Had a few over run and decided to try them in my .357 DW 10". First shot was high. Settled the sights at 15 yds and ran the rest of the cylinder. Wow. Did I mention I love HT. Even with my wifes snubby they were less than an inch. Now don't laugh, these were a 135 rnfp just sized to .358. Same one I use in my nine but .358. I have a new plinking round. Out of a 10" DW it was like a cap gun. No lead in either platform but looking at the throats on my wifes snubby how it didn't pull the coating off I will never know. Here is that screamer group from my Dan. Both barrels were like mirrors at the end of the session.

Our house is protected by the Good Lord and a gun and you might meet them both if you show up here not welcome son!

epa has shut down last lead smelter in USA. Maybe we can open it again in few years if we go vote.

Been reading 88 pages of this thread. Must say it sounds awfully interesting.

When I get a few dollars ahead, I'll be buying me some of this.

Can't wait to do some lo tech hiTek mihek boolits.

Already got some hardware cloth, an oven, and handling materials, oh, and some unlubed projectiles.

"What makes you think I care" ........High Plains Drifter

Rick C.

Great, its good stuff! Glad your here. Ausglock can make it easy. Just keep in mind its a stain and not really heavy like paint. Some that new cat#2 or 3 is really slick. I use the hi-tek 500 mold release also when i cast. Just bought a new rcbs pro melt and sold Lee 20lb furnace on ebay in 12 hours. Preventive measures for the future. Your shop, dies, fingers, barrels,etc will be cleaner.

Gunoil, that has been a major problem here in Missouri. The plant has been sued by the local residents for lead contamination BIG MESS!

http://www.usaprepares.com/financial...-close-in-2013

Gatewaybullets.com

Today I coated some 475 boolits and some 38 boolits. I was having issues getting good coverage on the 475s but then added some of the 38s to the mixing pail and the 475s coated much better.

I have had no problems coating the boolits then letting them dry in the sun for 15 minutes. Today the DVOM was reading 88 degrees in the sun. Maybe when it gets cooler I may have to let them dry longer.

I bought some gold recently and found I really like it. It does not add to the boolit diameter as much as the Red Copper so sizing is much easier.

I have used the Red Copper to add to the diameter of the 314299 for my Mosin Nagant and at around 1,600 fps to 1,800 fps it seems to work just fine.

I seat the gas checks in my RCBS luber/sizer using the Lyman gas check seating tool so the boolit barely enters the die. This way the boolit is not sized. I did try seating after coating but it did not work well with most of the checks not seating on the boolit shank as far.

I also have been using 5-1-6 ratio but recently have added additional acetone to the top coat as the appearance is better and it does not seem to affect anything else.

Thanks leadman your post answered a few of my questions. Nice to know how to overcome the gas check seating and that some increase in diameter with good results is possible. Looks like the Lyman lube sizer won't be mothballed, not that it would have anyway as BPC will require a good lube even if coated.

I should say I'm in Aus so have played with coated commercial cast on and off for the past 20 years in pistol cals and pistol calibre rifles. Haven't tried dedicated rifle projectiles coated.

Don't think I have purchased a box since I started casting about 10 years ago and discovered I could produce boolits that were more accurate than I could buy.

Unfortunately the coatings have only very recently become available to the home caster in Aus so hands on experience here is also limited.

A few of the blokes at my club have run some accuracy comparisons using commercial swaged with both coated and conventional lubes.

From their testing they concluded the conventional lubed projectiles were slightly more accurate but not by enough to worry about.

I need a new project. I'm bored with coating cause it is so easy to do and the results are always perfect.

Always wanted to skydive.........

Wrestle crocs........

Breed Drop bears.......

Manage a brothel......

Make tabacco pouches out of Kangaroo scotums........

Hooroo.

Regards, Trevor.

Australia

thanks for that link gateway b..

Anybody like 380's? Heres some hi-tek-green hornets/108gr/makarov nose.

Made this vid last nite on lee loadmaster

http://www.youtube.com/watch?v=5SJ9meSDiio

nice vid, Gunslick.

But where are the drop bears???

Hooroo.

Regards, Trevor.

Australia

Ausglock, I highly recommend skydiving - initially it's a huge adrenalin rush and after that just a lot of fun. Only made 250 jumps before I started flying but there's nothing like stepping out of a plane at 13,500 feet above ground.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |