|

|

|

Looks good.

All the R&D, pain and testing for a Blue has paid off.

Now... for Pink and Purple.

Hooroo.

Regards, Trevor.

Australia

I don't usually load this soon after casting / coating but these are dead soft anyway. I used a .359 expander for .3585 sized bullets. Redding profile crimp may squeeze them tiny little bit but less than half a thou.

Offhand relaxed plinking in low light.

A pulled bullet:

Petander

What was you bake temp and time in the oven? And how did your wipe test go?

Last edited by Avenger442; 01-01-2020 at 05:51 PM.

While I work at it, it is by God's grace that it happens. So it is best I ask him what, how and when before I start..

More plinking. These seem to fly straight and do not lead,it's time to do proper group testing soon.

Today I tried a classic mild 38 Special wadcutter load around 820 fps using whopping 0,21 grams (3.2 grns) of Vihtavuori N320. Too dark to chrono. I was above 1000 fps yesterday with 3N37.

Recovered some bullets from a pine tree trunk - my BHN is 5!!! TruBlu is still hanging on there. And this is my first TruBlu bake ever so I'm no pro at all. But my barrel and cylinders are clean.

Loading soft bullets really really needs a proper size expander. Also long enough. My NOE here is .359, bullet being .3585. Seats straight and nice.

All in all I'm impressed by Hi Tek,again.

Really like those soup can bullets for punching holes in paper. Slide sent me some with a hollow base when we were testing PC and HiTek. Those bullets were very accurate of hand. And I'm no bullseye shooter with a hand gun. Slides a really nice guy. He even sent me some Orange and Blue bullets for Christmas.

I've been working with the Tru Blue but just haven't got it to stay blue and pass wipe test. Still working on it and talking with Donnie. I think he said he had some success with the blue. Obviously with Petander's post it is doable I just haven't got there yet.

Before Bake

After Bake

Bullet by itself on the left was 4 min between 180 C and 190 C. Failed wipe test. Came off down to lead.

Bullet by itself on the right is 6 min at same temp. A little color on the wipe but not down to lead

Bullets in the middle were 8 min at same temp. Very little on cloth when wipe tested.

Those things with the wire attached are two coated 45-70s. Wires run to two remote thermometers.

Like I said still working with it and will post when successful.

Last edited by Avenger442; 01-02-2020 at 03:08 PM.

While I work at it, it is by God's grace that it happens. So it is best I ask him what, how and when before I start..

Oven temp is such a strange thing.

My 2kw wall oven dial is pretty accurate when we talk air temp. I have both a digital and mechanical thermometers in there. I set oven to 190°C and they all read 190.

But I have a radiant heat issue. My bullets get hotter than the air and I know my oven by now so I baked TruBlu in 180°C. That way the bullets get to 190°C. My normal bake is 190°C air temp,then my bullets get to 200.

I have checked temps with two different IR thermometers for a year now and I trust them - without knowing the real,absolute temperature. Coatings are reflective,plain lead reads a bit differently. My oven bakes hotter on the right side. All that jazz.

Confusing enough? Not really, I dial 190°C for 8 lbs, 8 minutes,all good. For TruBlu, I dial 180°C again 8 min.

I remember when I used 200°C setting, the bullets hit 220 °C at nine min. Air 200 all the time.

Oh,IR reads differently compared to a probe in the same bullet.

So I don't really know any absolute,real temps. But a powerful oven is easier than a little one,I'm on my third oven now.

Avenger 442 I sent you a p.m.

Boolits !!!!! Does that mean what I think it do? It do!

To help with understanding the "down unders"

Pretty good, unfortunately some of the younger folk these days don't appreciate the inherent subtlety and conciseness of Australian colloquialisms.

A minor correction, however, "howya going" is generally used as 'ow ya goin', a bit more relaxed than the Queen's English version. The answer is often "orright".

I've been working with the Tru Blue but just haven't got it to stay blue and pass wipe test. Still working on it and talking with Donnie. I think he said he had some success with the blue. Obviously with Petander's post it is doable I just haven't got there yet.

Before Bake

After Bake

Bullet by itself on the left was 4 min between 180 C and 190 C. Failed wipe test. Came off down to lead.I am guessing, that the temperature you were quoting may have been oven temperature

Bullet by itself on the right is 6 min at same temp. A little color on the wipe but not down to lead

Bullets in the middle were 8 min at same temp. Very little on cloth when wipe tested.

Those things with the wire attached are two coated 45-70s. Wires run to two remote thermometers.

Like I said still working with it and will post when successful.[/QUOTE]

Two things that need explanations is

1. If coating/projectiles has been subjected to 180C for adequate time, so coated cast is at 180C, why was there a total wipe off????

2. With over baking, there seemed to be also a wipe off, and colour became Green.

These two things are of concern, as it does not make sense.

Under baked coatings will wipe off with solvent.

Over baked coating will change colour but should not wipe off with solvent test.

Something is wrong with these results.

Two things that need explanations is

1. If coating/projectiles has been subjected to 180C for adequate time, so coated cast is at 180C, why was there a total wipe off????

2. With over baking, there seemed to be also a wipe off, and colour became Green.

These two things are of concern, as it does not make sense.

Under baked coatings will wipe off with solvent.

Over baked coating will change colour but should not wipe off with solvent test.

Something is wrong with these results.[/QUOTE]

I agree Joe. As you know I'm a fan of the coating especially the 1035 Gold in my rifles.

Have been considering what might be wrong. Do you think it might be a lack of catalyst? This being the powder it might have settled out to the bottom of the jar? A good stirring and shaking up might fix that. Or I could add some of the liquid catalyst that I have. Quite frankly I'm not sure what the problem is. With the measuring of temp and time I'm pretty sure they are right.

Another note is that all times turned green.

While I work at it, it is by God's grace that it happens. So it is best I ask him what, how and when before I start..

I agree Joe. As you know I'm a fan of the coating especially the 1035 Gold in my rifles.

Have been considering what might be wrong. Do you think it might be a lack of catalyst? This being the powder it might have settled out to the bottom of the jar? A good stirring and shaking up might fix that. Or I could add some of the liquid catalyst that I have. Quite frankly I'm not sure what the problem is. With the measuring of temp and time I'm pretty sure they are right.

Another note is that all times turned green.[/QUOTE]

Where did you get the TRUBLU powder?

Is this the one that was tested by Donnie?

If it is, I also had that same batch tested locally before we sent it for evaluations.

You can try adding some liquid Catalyst to a premix of the powder, but I feel that there is something else not right.

What was Donnie's suggestions?

I have no suggestions for Avenger,sounds strange.

I'll give TRUBLU another minute next time I bake, probably tomorrow. Just to see what the colour says baked longer, here in my oven.

I'm totally in love with these mild H&G wadcutters and my "new" Mod 14 from 1972. But I gotta say,being otherwise a clean gun,that thing had the hardest ancient carbon deposits in cylinders,ever. Tiny little rock hard rings.

Colour coding loads comes in handy here,again. Yeah, TRUBLU for target, CandyApple for +P Wadcutter... great fun!

Last edited by Petander; 01-03-2020 at 08:18 PM. Reason: Add pic

Joe

PM sent in reply to above.

While I work at it, it is by God's grace that it happens. So it is best I ask him what, how and when before I start..

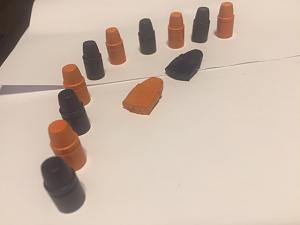

One more minute. TruBlu got a little darker as expected. But not green.

In the pic here they look much darker than they are,a very difficult light now.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |