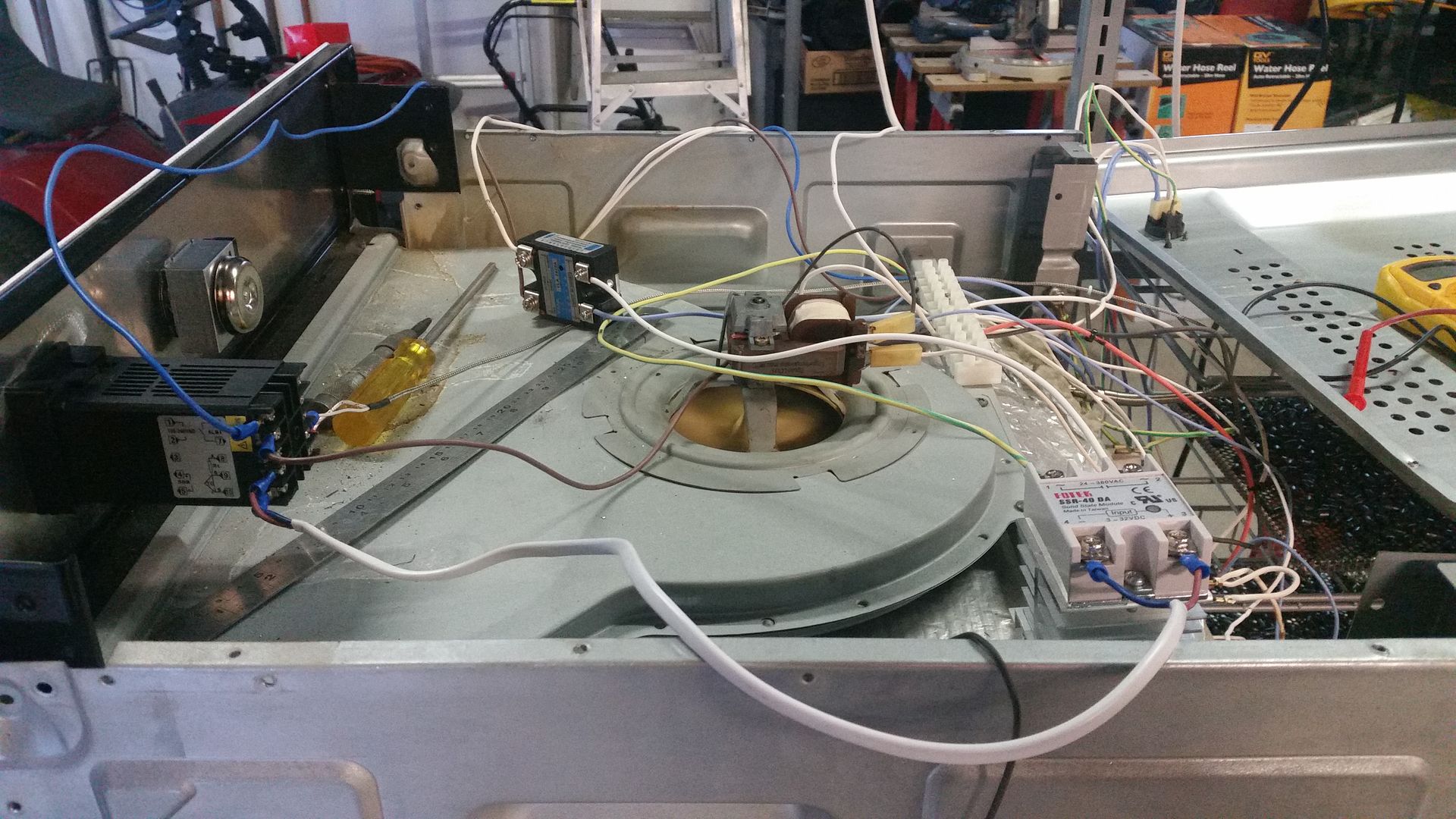

Rich, my Gunmetal boolits are what I would call an "oily black" colour (I gave up worrying about the final colour, as long as they work that's all that matters). I also found that in my little oven I had to bump the temp up to just under 250C to get the Gunmetal to get a Gunmetal colour (using a PID to control the temp). The Bronze and Zombie Green both work at "normal" temp (200C) and at that temp the Gunmetal comes out green, but still passes all three tests - wipe, smash and shooting!

Try increasing the temp a bit, I've found this stuff to be reasonably forgiving.

|

|

|

Reply With Quote

Reply With Quote