We have been discussing for some time some of the coatings that came across the P pond with a little too much color in them. Donnie said he thought it was just the reds but I've also had a problem with dark blue and black 1035. These will deposit a little color on the rag when doing rub test. But coating will not come off down to the lead. Some will leave a little color in your barrel which cleans out like powder residue. It would help to analyze you problem if you could post a photo of the rag and bullet used in the rub test. It's probably just one of those batches with too much color. Joe waisting his resources

If you do get some where they rub off all the way to the lead on first rub test you can bake them a little longer and fix it. No amount of baking will fix the batches with too much color in them. Just load em and shoot em. Mine that are that way leave no lead in the barrel. Which is the main objective anyway. If they fail a smash test, that is big flakes down to the lead, then start all over means toss them in the melting pot and re cast. The only way to fix that problem.

This is the non-professional coater speaking from my experience with Hi Tek. Ain't no complaint intended.

|

|

|

Reply With Quote

Reply With Quote

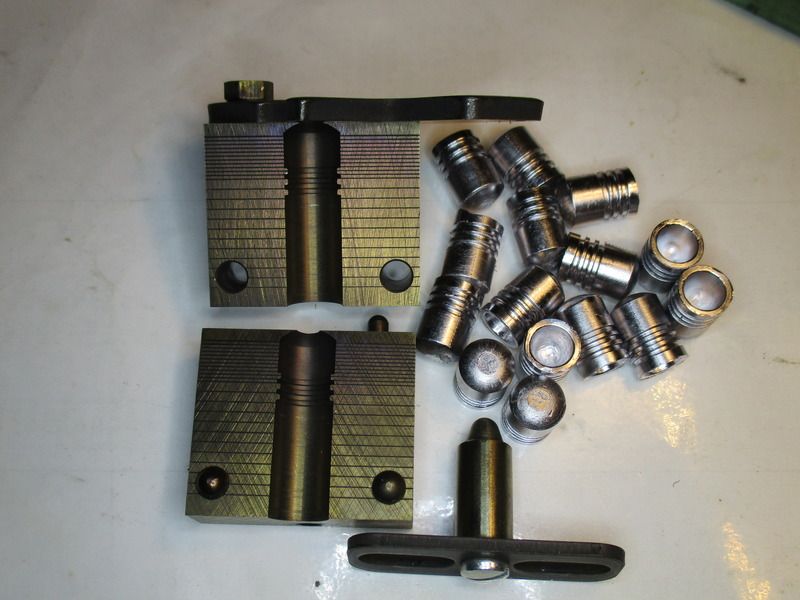

you can see the lead spot where it came off

you can see the lead spot where it came off