I have experimented on how to seat gas checks to where they are straight, square, and fully seated.

The super easy way is like this, take an old push through seater and place the seating stem inside of it with a little spare lube. Screw it into your reloading press. Then use a second seater stem in the shell holder.

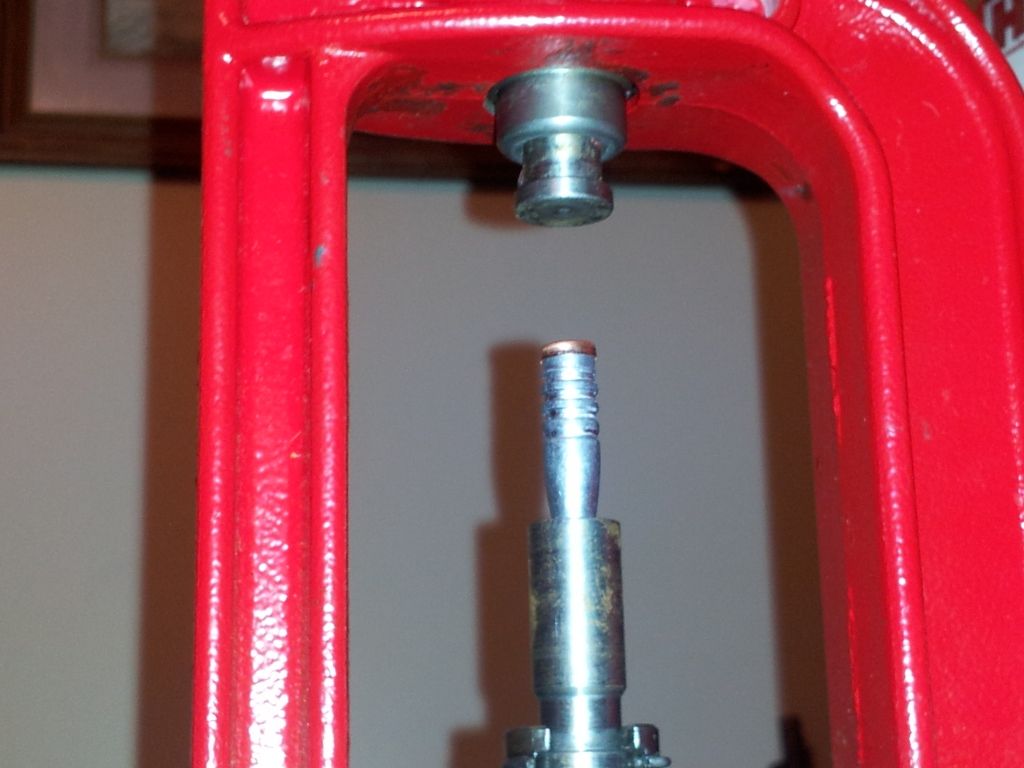

Now sit a boolit nose down on the seater stem as shown (NOE 311-165 and prototype copper checks pictured) and ram the press home... GENTLY!!!!!!

This seats the gas check perfectly square and allows you to feel it bottom out.

Now you say "But Josh! I have round nose and spire point boolits! That will damage the nose!"

Well I have an answer for you! I have em too and done figured it out.

I use a standard shell holder and place the appropriate top punch in the hole in the center, some shell holders need enlarged by about .002.

Seat the boolit in the top punch and gently ram home, this will not damage the boolit nose and self centers easily.

I hope this helps someone out there!

|

|

|

Reply With Quote

Reply With Quote