Here’s my take on a PID Lee pot.

My first pot from 1985 and it is on it’s second heating element.

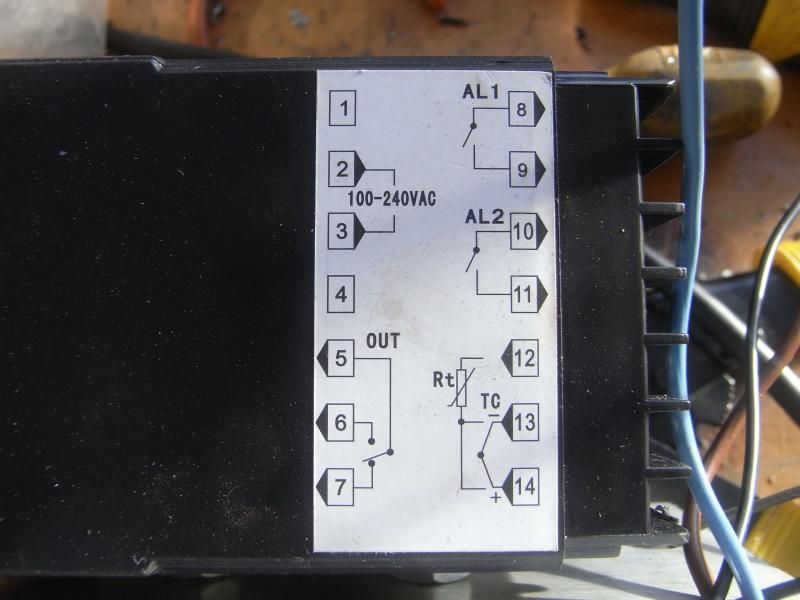

I used a PID from dx.com that came with a thermal probe delivered for just $17.80

http://dx.com/p/digital-temperature-controller-66334

It will go to 400degC~752degF

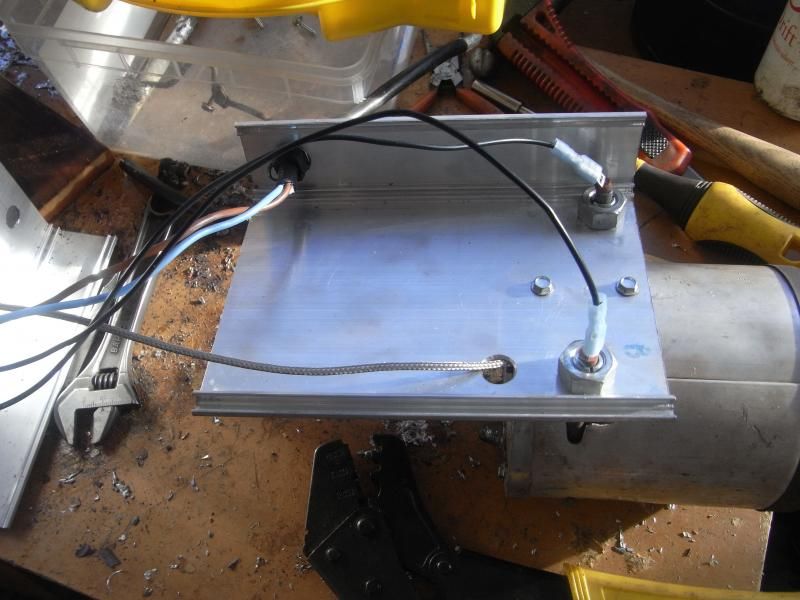

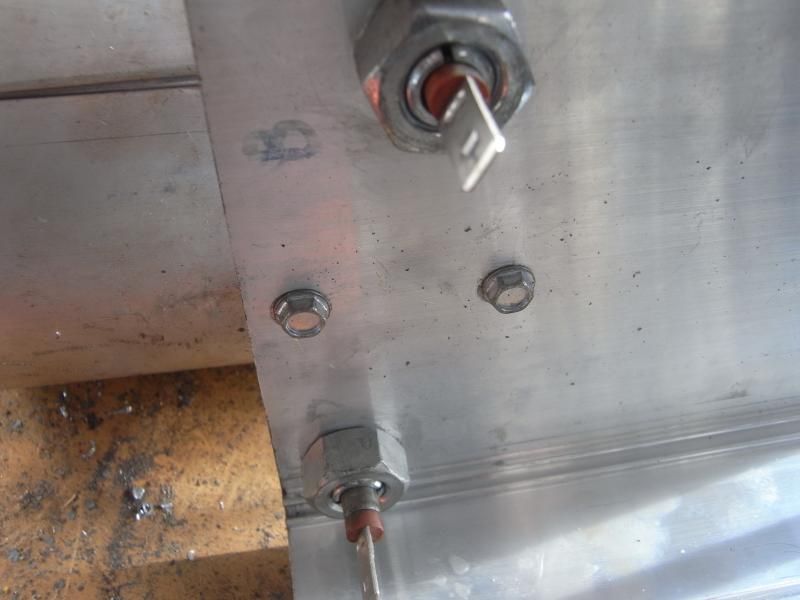

1: I started by dismantling the pot and polished a spot on the bottom for the probe mount.

2: The thread on the probe is ¼-20 and i made up a brass mount that i (high-temp) silver soldered onto the pot. (What I could with what I had!) You can weld 2 nuts onto the pot and achieve the same but remember to close the hole so the end of the thermal probe has something for proper contact.

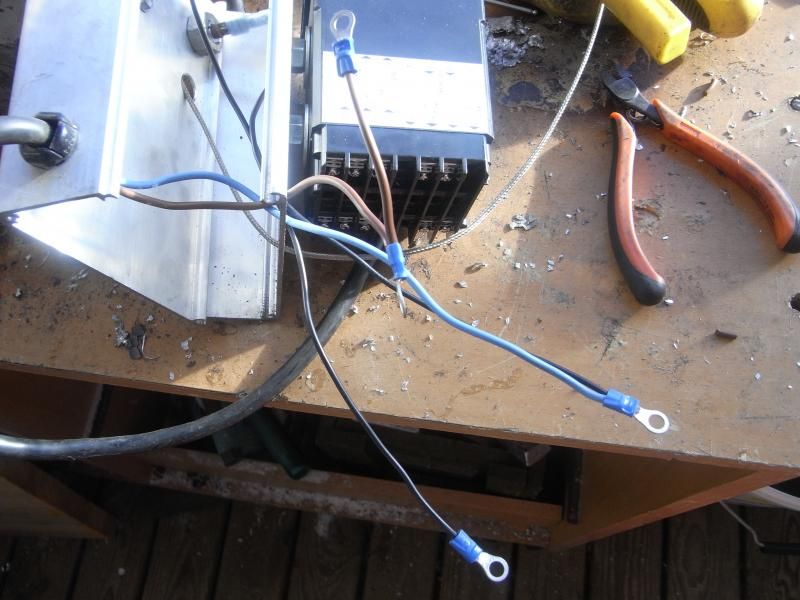

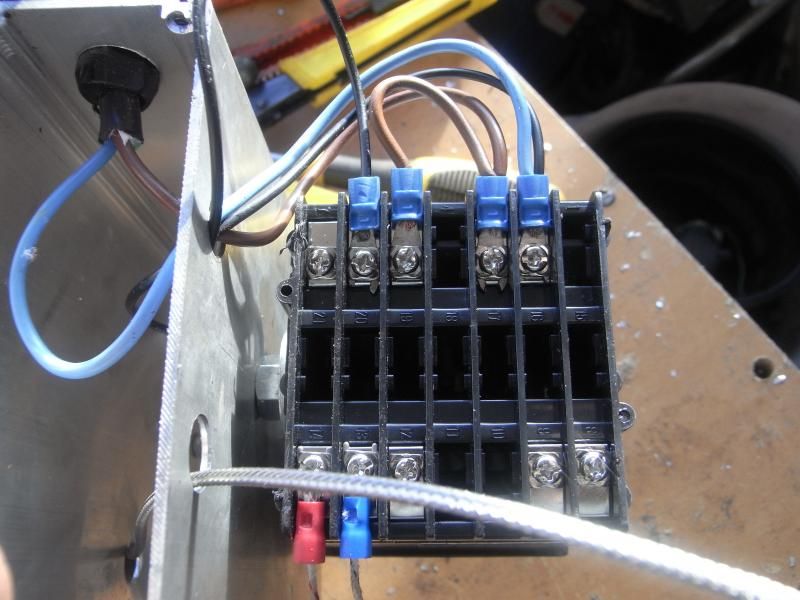

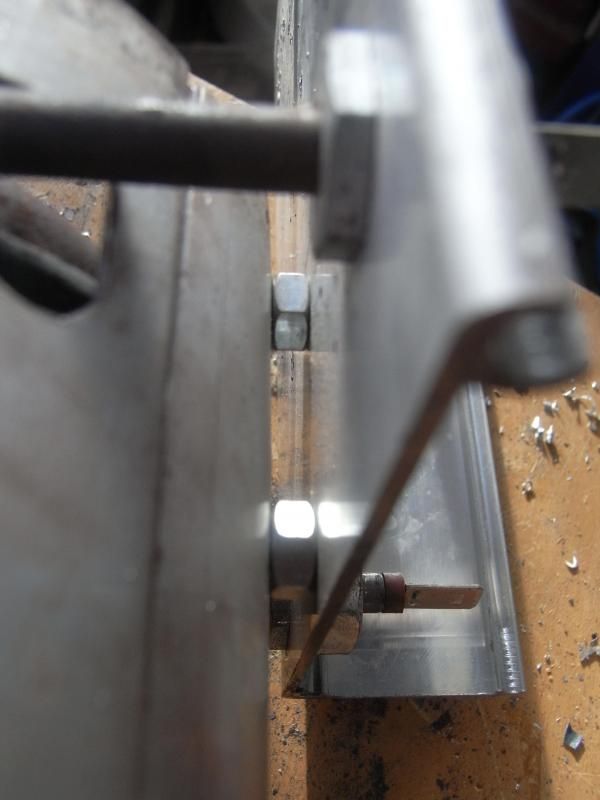

3: The controller electronics will pop out and make mounting a breeze. I was lazy and used nuts and washers for spacing when I mounted the controller house onto the back of the pot stand. I added some holes for wires.

4: To counteract the sad sagging from pic. 1 i used more nuts as spacers with some self tapping screws into the pot couling.

To be continued.

|

|

|

Reply With Quote

Reply With Quote