Range report, or "I finally got around to taking this thing out and shooting it".

I am still collecting odds and ends toward fitting a cast bullet to this rifle. JohnH sent me a SC Lee 379-250-RF mold a while back. fa38 sent me a batch of SAECO 571 bullets (300 gr, plain based, tapered). Still working on a .382 expander plug with RedneckDan. Ordered a .382 H&I die from Buffalo arms. Got in on Boomer Mikey's 381-268-RF Group Buy. Ordered up some 383/265 bullets from Bullshop to tide me over till the group buy mold arrives.

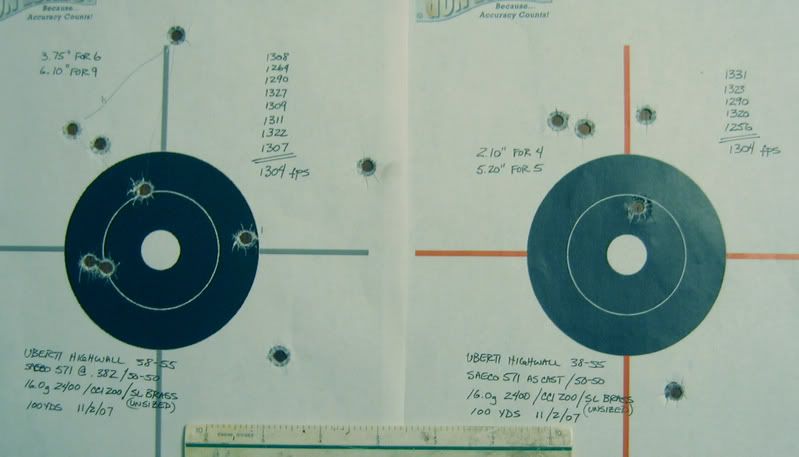

The objective of the excercise today was to fireform 50 of the Starline 38-55 (long) cases to the chamber. The Saeco 571's are a great looking bullet that casts at .384 on the base band and I would like to shoot a few to see how well they stabilize in the 1:18 twist before ponying up for a mold. The largest expander plug I currently have is the .379 that comes with the RCBS 'Cowboy" die set. I am hoping to finger seat the Saeco 571 in a fireformed case rather than jam it down a case with an inside diameter of .378/.379.

I had about 75 of the Lee 379-250-RF already cast up. Some of these were .379/BHN 8 and some where from a run where I had beagled the mold to get a .381/BHN 12. I expanded the cases to .379, finger lubed the as-cast bullets with NRA 50-50 and loaded them up over 16.0 gr of 2400. Seated to a COL of 2.556" the .381/BHN 12 bullets lightly engraved in the rifling and the .379/BHN 8 bullets did not.

I put the rifle on the bags and did a quick boresite to get the tang peep set close. The first five rounds I used to finish the sight settings. It took a lot more elevation on the sight than I had anticipated. The rifle came with a short, dovetailed front post. I like the sight picture this gives for target work better than the front bead on my top-eject Winchester 94. I am glad it is not taller than it is given how far I had to crank up the tang peep (47 clicks up from bottom).

I shot a few groups. The .381/BHN12 bullets gave me 1.0" to 1.50" groups (@ 60yds) and the .379/BHN8 bullets ran more on the order of 1.5"-2.0" (@60 yds). This was better than I had anticipated given the under-sized bullets and a random load. I fired the last 10 over a chronograph and got a mean velocity of 1452 fps.

The Starline (long) cases fire-formed out to an inside diameter of .3830"-.3835" (caliper measurement) and shortened ~ 0.010" in the process; started in the range of 1.120" to 1.125", fire-formed to 2.110" to 2.115".

Now to load up some of those Saeco 571's. If everything goes well the rest of this week I may get a chance to fire them off this Friday...

-ktw

|

|

|

Reply With Quote

Reply With Quote