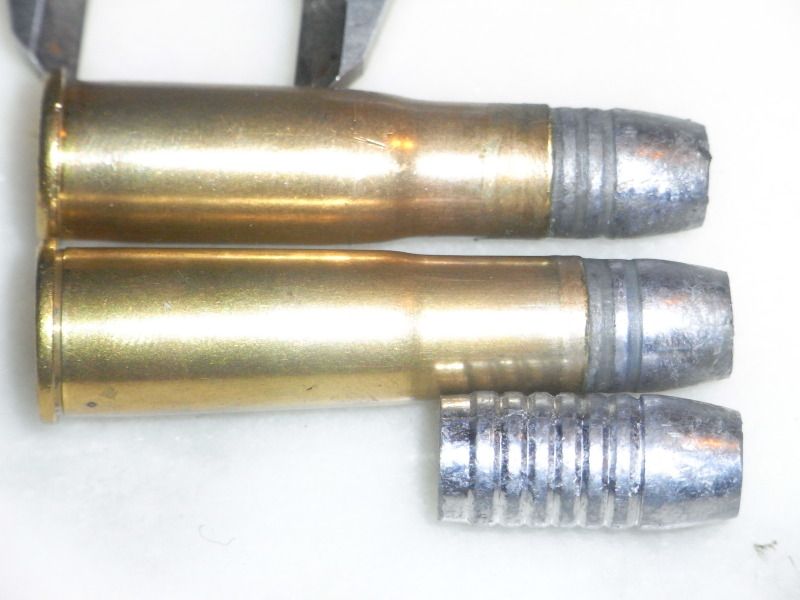

I've shot the Vetterli .41 less than 20 times. I cast my own bullets out of soft lead, but not pure lead. I use black powder. I keep seeing specks of lead on the cleaning patches. It could be from the previous owner, since this is the first time I cleaned the barrel extra well. If not, should I use softer lead, harder lead, or just accept it and keep scrubbing?

If you ever get the chance to shoot a Vetterli, you will like it. Very little kick and very accurate.

|

|

|

Reply With Quote

Reply With Quote