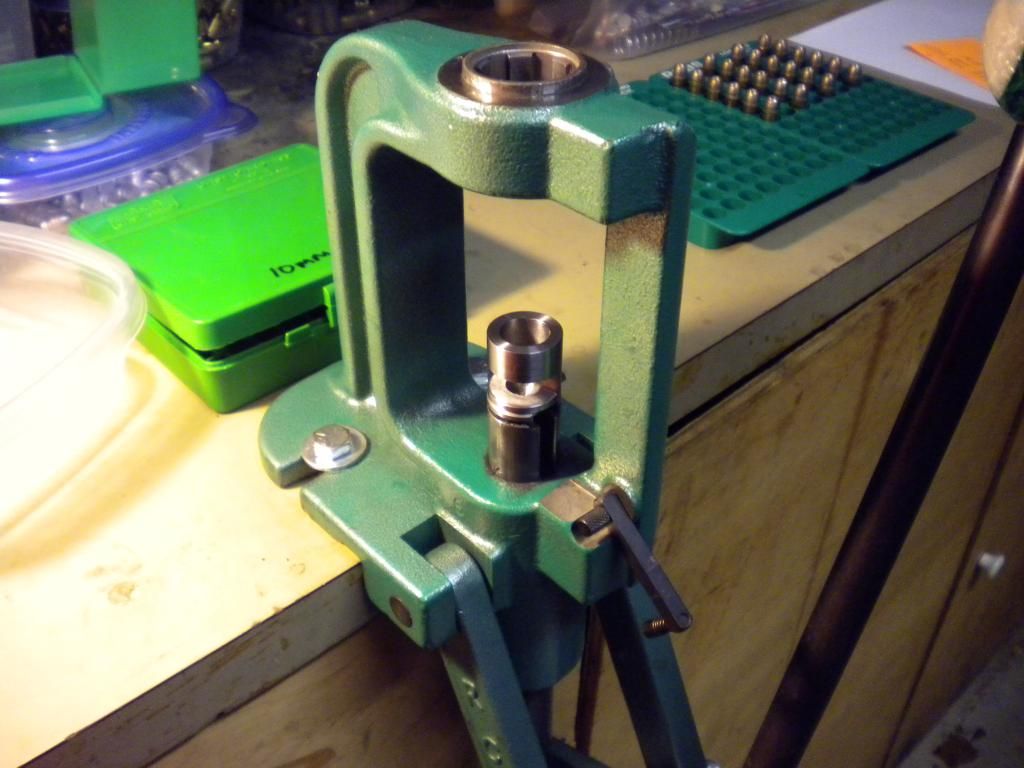

Why won't you show us, with some photos, what your threading set up looks like ?

When you attempted to thread, what did you have set up...what machine do you have ?

What didn't work ? What part ?

No worries, Mate. The guys here can get you to where you want to go !

DoctorBill

|

|

|

Reply With Quote

Reply With Quote