After reading numerous PID threads, I decided to build one for my Lee 4-20 casting pot.

I re-used an old comp power supply & stripped it out,

all wires came from a stripped out washer machine

re-used the 120v (15a) female panel mount socket

installed a Link Depot (12a) 115V Fan (80mmx80mm) to to pull the heat out of the power supply,

installed in-line fuses (12a) for the power-in and out,

installed (120vac) Neon-red LED lamp assemblies for the power-in and out,

installed a 15a 4-position terminal block

installed a 1/16 PID Temp Controller (SYL-2352)

installed a 25a SSR

installed a K-type high-temp thermocoupler

installed a DPST rocker switch 250v (15a)

installed 120v (15a) us panel socket.

I'm sure I forgot something...

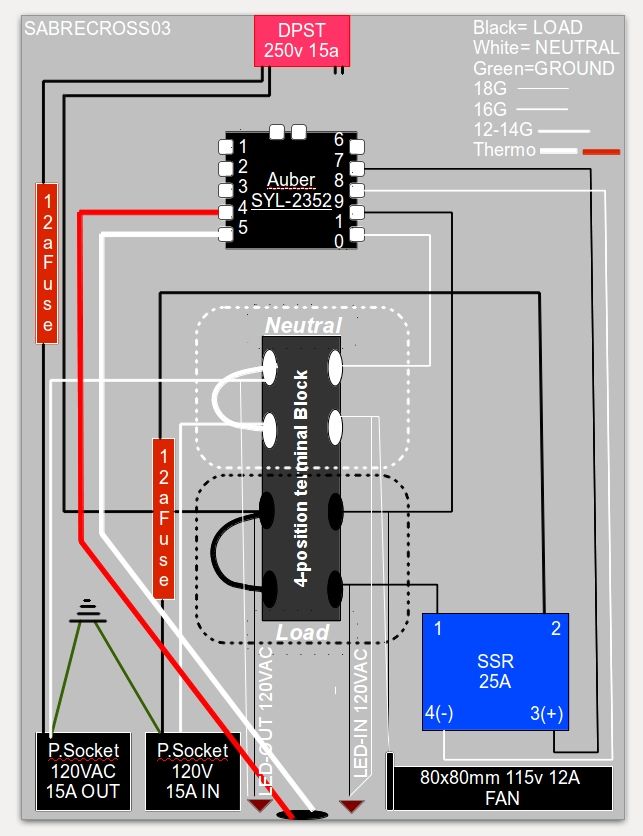

Schematic:

Final product:

Rear view:

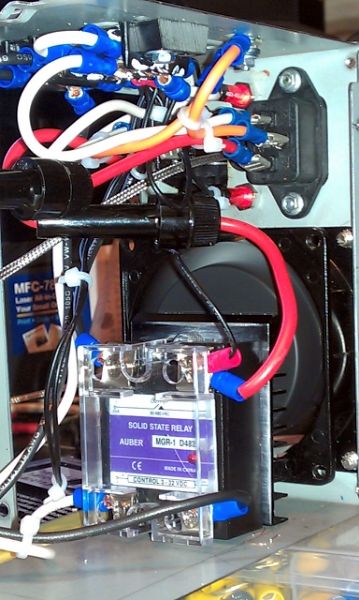

Inside view toward rear the rear: Terminal block mounted to the inside-top of box, SSR , Fan

Inside view toward front: PID controller and rocker power switch

Now to plug in the Lee 4-20 and program the PID...

And Please, no negative comments from the peanut gallery

|

|

|

Reply With Quote

Reply With Quote