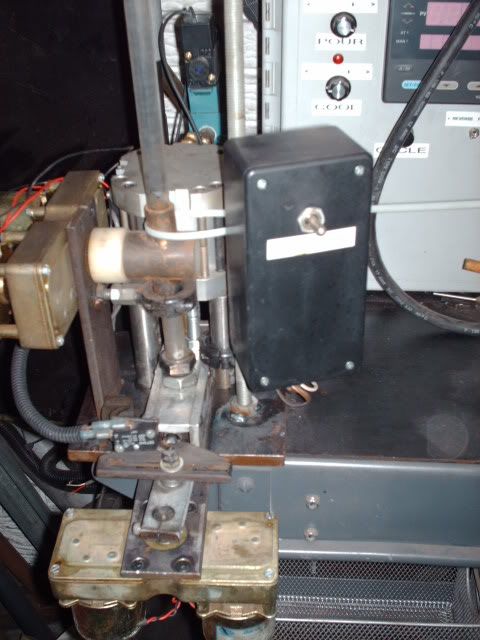

Sometimes I don't explain this in writing well enough and have been asked enough times about the bullet flipper I built so I can use the same bullet collator for my reloading machines with the sizer I built. So I took it apart and took some more photos.

The plastic drum has a blind hole, only drilled deep enough to have the base down bullet clear the steel tubing it rides inside of. I also realized that when I took the photo with the bullet sitting in it I put it in nose down but in use it would be nose up at that point.

The motor turns at the same rate as the feed motor on my sizer so it's never waiting on bullets.

The tube from the collator drops the bullet into the stack that enters from the top (base down). The motor rotates and a bullet drops in. It continues around 180 degrees and the bullet falls out into the bottom tube (nose down).

It could be made much faster with a larger OD "drum" with a lot of holes drilled around it but that was all I needed.

Had to edit it because I still wrote the description wrong, thank goodness for photos. Your welcome and it is as simple as it gets to do the job 100%.

|

|

|

Reply With Quote

Reply With Quote HATCH

HATCH