I'll gladly share what I found & theories I have for the unsuccessful attempt I had.

First off, you're perfectly correct that concentricity is of paramount importance and inaccurate machining will eat your lunch (was the largest problem for me at least). Too long of a boat-tail will amplify imbalance/concentricity issues, a problem I discovered only after spending the time to cut mold blocks for the bare slug. This done with a D bit and drill press, I think lathe bored blocks would've gotten me past40 to 50% of the problems. Unlike your design, my boat tail check was designed to be almost a 1/4 jacket as I deleted the bottom lube groove and extended the check/jacket up to attempt a gain in grip surface parallel to the bore for check retention both in the bore and throughout boolit flight (trying to eliminate flyers due to checks blowing off in flight).

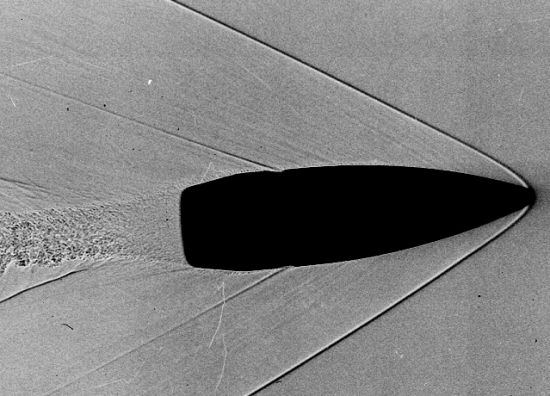

In theory it should've worked, and may well do so if manufactured to design specs (and this is where Pat Marlin may be invaluable to collaborate with) my checks were made from .020 soft copper sheet stock in a "check-maker" I made. They came out looking quite good to visual inspection but in actuality they had thin & thick spots in the walls from my home made swaging die. I fell certain the problem was forming too thick stock and forming in one stroke from flat to finished check. These added to the slightly unconcentric boolit produced a wobbling boolit flight that was out of control. Wild flyers in groups shot in excess of 500M finally led me to track down the keyholing boolits. Enlisting the help of a friend who's a surveyor, I was able to post targets from 100 to 900M out. All targets were carefully placed so as to retain the same point of aim and allow one shot sent @ POA 100 yds to strike every paper back stock. This showed me the flyers were keyholing, but weren't consistent, the tail tears from 500 to 900M looked like clock hands.

This effect I believe was induced by imbalances as they were negligible with moderate loads (1800 to 2300fps) but as speed climbed, so did the violence of the wobble, finally reaching a point where the wobble increased air resistance enough to decrease the trans-sonic range to where I saw tears that told me the boolits were tumbling and/or spinning sideways and flyers jumped from 4 to 7 inches out of group area to landing up to 3ft out of group area.

Your shorter check should help with the erratic forming issues I had, so if you can get a concentric slug to start with I think you'll be halfway there at the very least. Should I think of anything I missed telling you about my experiment, I'll post that up also.

Best of luck brother, I'm pulling for ya to succeed!

|

|

|

Reply With Quote

Reply With Quote