That is some really nice work!

I want a couple full size cannons and need a new project.

|

|

|

That is some really nice work!

I want a couple full size cannons and need a new project.

Have any of you tried this?

I have some. It is slow, and a little tricky to use for a really good outcome. If anything, it can be used as an agent to speed up the natural patination process. Seems very sensitive to any oil or contamination on metal. At first you'll notice uneven oxidation forming. It requires patience. Might use it after firing and cleaning for a few times- the oxidized finish then would have time to "even out". Again, might have a use just to speed up the aging process of the surface.

Also, those small cannons just seem to bring out the imagination and kid in some of us

Trust but verify the honeyguide

Working on the axles today. The cannon builder is gonna be sending me wheels and the cap squares so waiting on them to mount the cannon and finish the axles. Still deciding the finish on the cannon

If it were mine I'd find or make a mold for a bore sized ball and cast some lead balls. Get some cannon fuse. Find a range with a good tall backstop. Load maybe 50-100gr F blackpowder (starting with something like 50 gr), ram a ball on top, insert the fuse, aim at a large cardboard target in front of the backstop, light the fuse, step well back and to the side- Wooom!

Oh almost forgot!- a tip. Use a large toothpick or even a bamboo skewer as a powder vent pick for inserting the fuse into the powder charge and if fired level or down angle for sure use a little wadding to keep projectile from moving away from the powder.

I know some cannoneers who use small metal cans that are bore size- then melt lead and fill the can or some simply mix a little concrete to fill the can. Makes a very acceptable projectile. The trick is to find the right sized metal cans for the lead or any paper or plastic container for the concrete.

Of course the manufacturer of the cannon should have all the recommended loading info.

Last edited by fouronesix; 10-26-2012 at 07:55 PM.

Trust but verify the honeyguide

I think that the board needs a cannon section

That aside,

I've run into a few folks shooting a homemade cannon out in the AZ dessert. One thing that I remember being told was the it was better to set them off with a cap & hammer gizmo rather than a fuse, because the time lag of a fuse allowed time for somebody on a dirt bike to show up out of nowhere at just the wrong time. It sounded kind of like an accidental near miss or two may have occurred in the past.

“an armed society is a polite society.”

Robert A. Heinlein

"Idque apud imperitos humanitas vocabatur, cum pars servitutis esset."

Publius Tacitus

Hay Tino

Here's the wheels they are almost done i got to do the holes & bushings tomorrow OK the wood is Oak and is laminated with the grains Cris cross.

I don't have any steel for the rims i thought i had but it was 6" way to big. I can't find the message with what holes you wanted was it 6 or 8 also they are 2 thick by 4.375 dia and dished 1/2"

Last edited by ClassicCannons; 11-07-2012 at 05:28 PM. Reason: updayed the pics

Hay Tino

On your mold it's going to be a duel mold 1 hollow point Bolt/Bullet and 1 round ball I'd like to see the hollow point one have grease rings but i'm unable to do that now without a CNC mill soon I'll have one

So be a little time on the mold maybe by the end of the week i got a lot of jobs to get done and order some more material too I'll also send along some !/2" rod for the axle's OK

On the mold you can pay what ever you want also

Thanks AUstin

Photo of a ramrod I made and pieces of the carriage drying

Side of the carriage drying, just need to put a coat of wax

I first stained the wood with walnut stain then 5 coats of dark walnut Danish oil from watco, first time using this oil we'll see what it looks like when fully dried. Then I'm gonna put a coat of minwax finishing wax.

Great work on the carriage can't wait till you get the wheels on i wish i had sent some brackets for the 1/2" axial now but i didn't know how you were doing it

Again Great job

Also i had tested the barrel with 1,500 grains with a ball load but 600-800 for a ball load or 1,250 - 1,400 with out a ball load should be good for you. At the 1,500 with a ball the cannon went back 10-12 feet on the carriage though it was a test and not meant to be the regular powder load.

How about a pair of Howitzers 1 3/4 dia by aproz 10-12" i have to do the scale to get the correct scale I'll include the AOP book that has all the measurements and include some of the hardware such as the trunnions the elevation screw sets the oak and the barrel.

If interested PM me thanks Austin

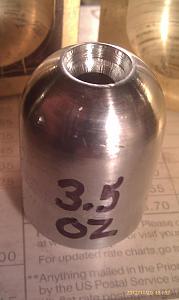

Here's the layout for the mold for the Cannon Tino

The mold is made from brass and will have 2 cavities one will be a 1" round ball and the other will be a 1.3/4" bolt/bullet with a boat tail (not shown) also it will be a hollow point.

Looking Great!

Here the mold so far i had to wait on a new cutter the one i sent out they ground to much offI wish i didn't have to pay the $68 bucks for their mistake

But your at their mercy uh

When you call and complain they onlyA long song and dance well a new guy here did your job. Perhaps i should tell people that when I'm late on a item

weel the bullet weighs 3.5 oz and has a boat tail for better accuracy. Like that matters

Also it has a round ball cavity I'd like o see which does the most damage

Some new photos of my build, still working on her

That is absolutely off the scale on cool! Nice work!

Years ago, I shot cannons with a couple of machinist buddies of mine. I have a small brass barreled .50 caliber cannon but those guys went overboard! One cannon shot a 3000 grain lead cylinder and used motorcycle wheels for the carriage. If you're interested in cannons, you might consider cost of firing them. That cannon with the cycle wheels used many POUNDS of black powder in an afternoon. I saw him hit a big gong at 100 yards and he sent it flying!

Flash

You Gotta Die Of Something........It May As Well Be Something That You Like!

Lovin' the Harley Idle: potato........potato...........potato

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |