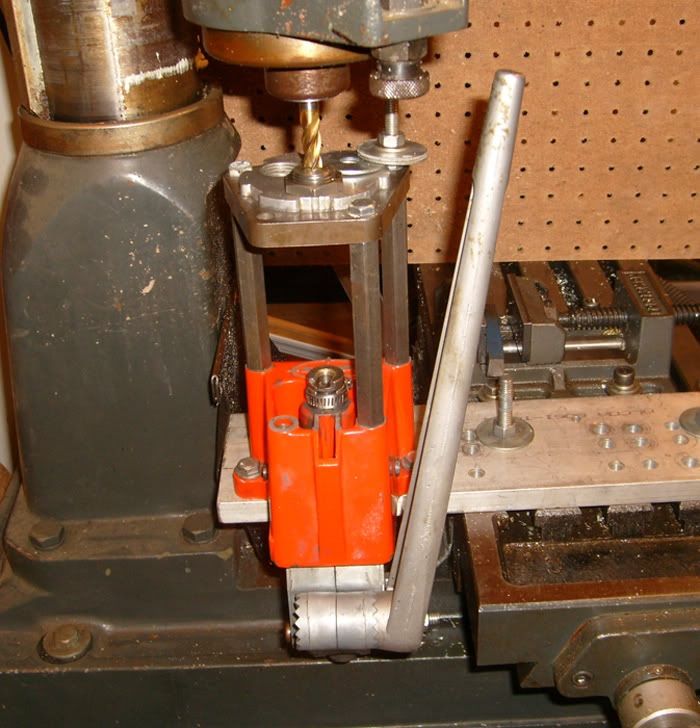

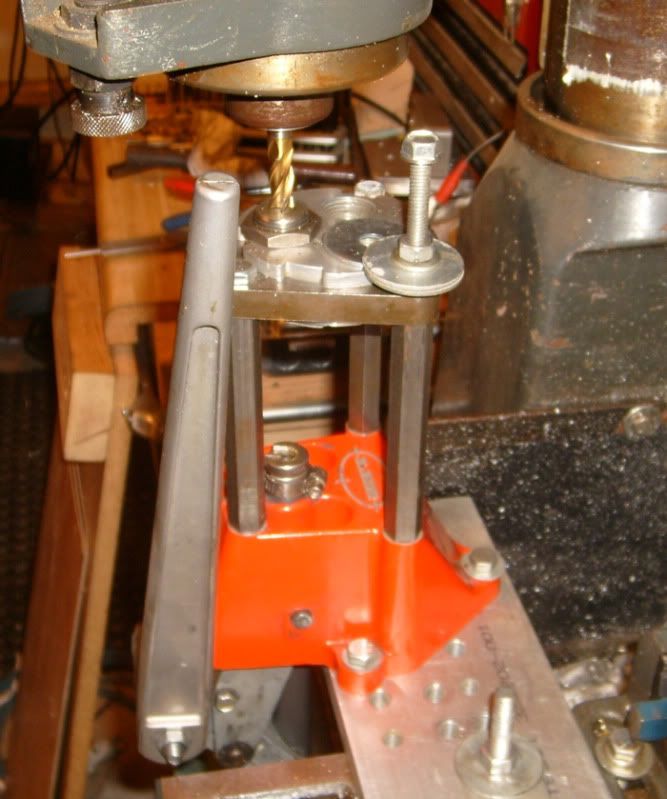

Here are some pictures of the setup I assembled to speed up my reforming and trimming operation.

I put my old Taiwanese Drill/Mill to work here; …..But the same thing can be done with any drill press that either has, or can be fitted with a lock on the spindle travel.

I used a Lee Turret Press here only because I have a couple of them sitting around for utility “side work”.

A you can see, the setup just clamps to the table, and is easily removed. Setup is very fast, as all you have to do is center the cutter over the die and set the height.

I made the case forming die by cutting down a Lee .300 AAC full length sizing die; …..But if you want to go “1st Class”, Redding makes a trim die that will do the same job. (The Lee die set was significantly cheaper, and I got a spare seating die and a shell holder out of the deal.)

This rig allows a .300 AAC Blackout case to be formed and trimmed to length with one pull of the handle. Case length is consistent to within .001”.

All that remains to be done is to make a “finishing” pass through a sizing die so that the neck expander ball can do its thing.

This setup makes short work out of doing 1000 rounds, and was well worth the small effort and even smaller investment!

…..And BTW: ….I did consider “going fancy” and buying a Dillon “Rapid Trim 1200” setup for one of my Dillons: …..But Dillion’s Tech Department told me that the Rapid trim was designed to take off a few thousandths, …NOT half an inch of brass! They politely explained that if I burned out the motor doing what I wanted to do, they WOULD NOT warrantee it! (….I know that other people are using the Rapid Trim for this operation; …..But I have too much faith in “Murphy” to “swim against the current” in this case!)

Kent

|

|

|

“.....Nuttier than a squirrel turd.” - An assertion by a fellow forum member

“.....Nuttier than a squirrel turd.” - An assertion by a fellow forum member

Reply With Quote

Reply With Quote