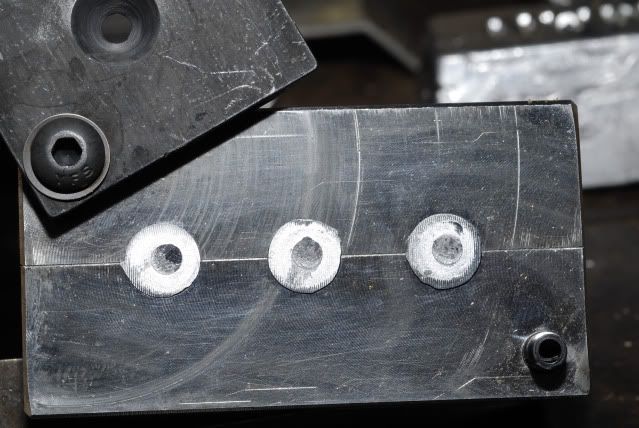

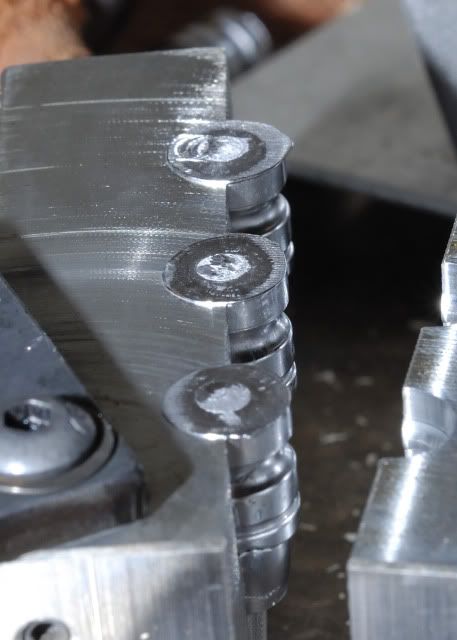

I think I may have a problem with a mold. The sprue plate doesn't seem be perfectly flat against the top of the mold and is creating overflow to a greater or lesser degree in the middle and far hole(3-banger). Consequently, it's impossible to get the boolits into the size die without pinching off the excess at the base and even then it's a push to get it in. Could this be a somewhat warped sprue plate or possible a problem with the mold itself, which is aluminum?

I tweaked the screw that hold the plate by loosening and then tightening and that seemed to do no good. If you hold the mold with handles attached up toward a light source you can see a little space between the plate and mold...especially from near mid point on forward. A yellow stickey edge slides right through the space.

|

|

|

Reply With Quote

Reply With Quote