I got one and need some info from anyone that has one.

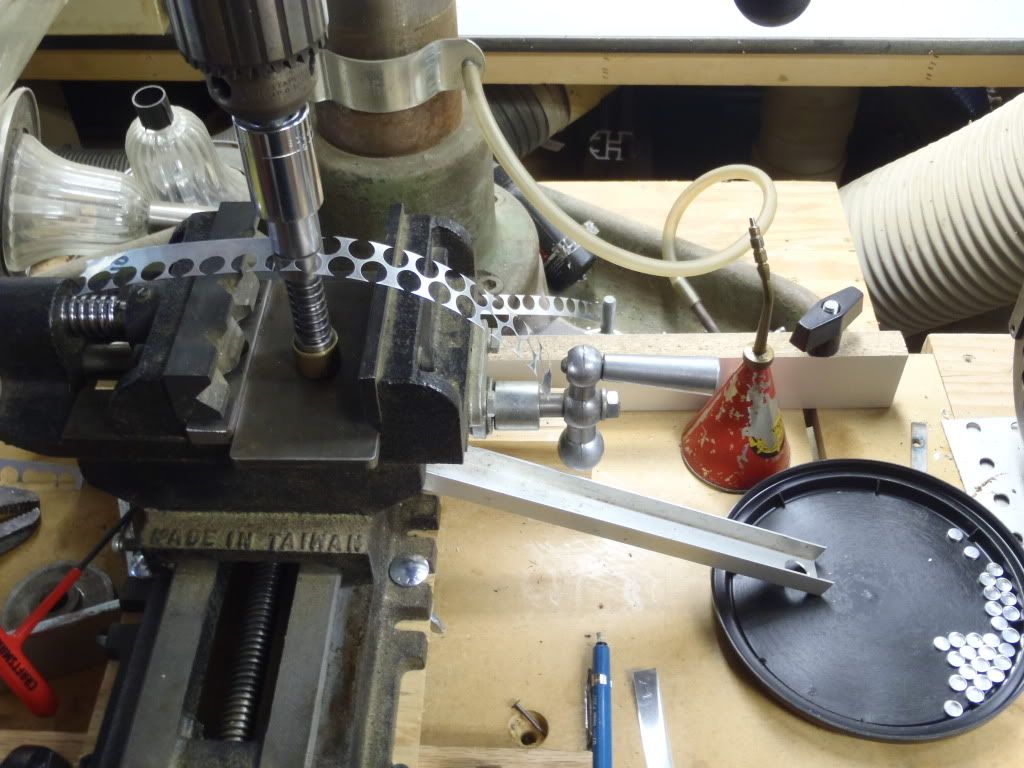

Bought an arbor press to use it!

What kind of gidget,gadget ,jig , or jury rig do you use to hold the checkmaker in the press?

It works great as is but being fumble fingered I figured maybe some one has the same problem I have (need 3 hands to make it work great).

Any info good or bad accepted.

bekeeper

|

|

|

Reply With Quote

Reply With Quote