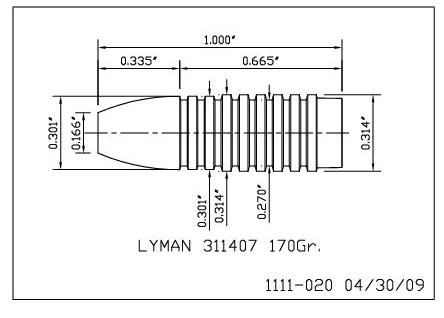

Got my mould today. Boolits drop .313 - .314 . Overshot the diameter just a tad. Boolits must be hammered from the mould. I use a bhn 18 corn cob ingot to "tap" on the hinge when boolits are reluctant to part from the mould. To get all 4 to drop from their cavities take upward of 15 to 20 solid whacks from my ingot on the hinge.

Perhaps this is indicative of the loverin type design with the large number of lube grooves making dropping difficult. I probably will avoid this type of boolit in the future. There was a raised edge on one side of the cavities that you could easily feel when you ran your finger over them. Dull tool maybe? I carefully stoned this down. When they do drop they are formed beautifully. Don't want a refund. Won't give up my mould. Just saying.

All honest efforts deserve an honest critique.

ammohead

|

|

|

ammohead

ammohead

Reply With Quote

Reply With Quote