you sent some baragel that needs the acetone [airc] it works on naptha also.

many motor cleaners have a base with napthene in them.

most case lube alcohols are rubbing alcohol.

which has a drying affect on the alcohols in beeswax, and solidifies the fats in some waxes [carnuba]

i have used the alcohol/lanolin case lubes to take the tacky out of b-wax carnuba lubes before.

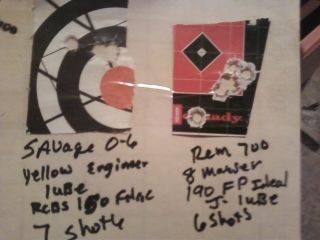

the cold bbl issue is a big one we have theorized that the bbls coating is drying up,oxidizing, or thickening and the first shot or two is repairing the bores condition.

i can alleviate it somewhat by wet swabbing the bbl with the liquid i use in my lube before i shoot but controlling the amount put in the bbl without affecting the conditioning in it is kinda tricky.

we were hoping the pao oils would alleviate this to some degree [within reason, i don't expect it to last a year]

|

|

|

Reply With Quote

Reply With Quote