I've got an old Modern Bond Wadcutter mold for the 38. I've had it for quite a while, and when I got it, I recall thinking that it looked as though the bottom driving band looked like it tapered to a smaller base diameter. Time goes on, and I hadn't cast anything in quite a while, and then the other day, I had the chance to cast again, and decided to try out the old MB mold.

After casting up a few of the bullets, I've got to say, the mold casts very nicely. But I've also got to say, I was right about thinking the base was tapered. I can only assume the base was tapered in such a way in order to deal with thickening brass?

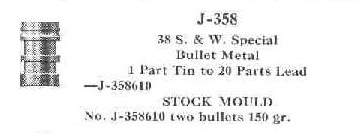

The mold drops at .360 from my alloy, but then the base of the bullet tapers to .350. the base driving band is very wide, and there is a crimp grove and slight full diameter protrusion on the front end of the bullet. The design is the J358 710.

Has anyone cast with this one before? Have any insight to the purpose of the taper if I'm wrong? Am I right?

I didn't take any photos of the bullets I cast, so I'll have to do that later. In looking, I see that the "standard" length for the J358 is 610, rather than the 710 on my mold. It would also seem that the taper occurs on the portion that makes it longer than normal.

Any thoughts?

Here's the J358 610 from the Modern Bond Catalog:

|

|

|

Reply With Quote

Reply With Quote