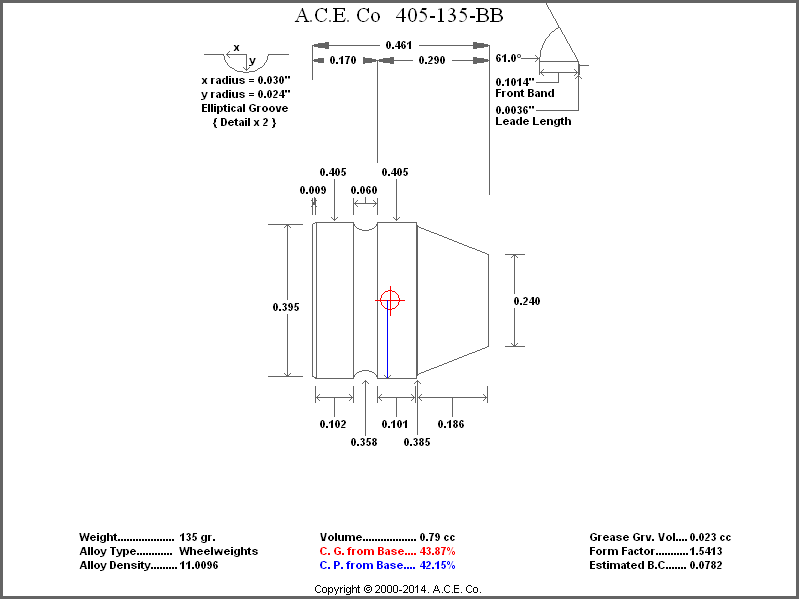

I contacted 45 2.1 and asked him if he could design a light weight .40 bullet for high volume casting and loading. I asked for something that would drop out of the molds easily and that would have a slight beveled base for easy loading in a progressive loader.

This is what he came up with.

I like it, but I would kind of prefer a conical nose instead of the semi wad cutter design. Any oppinions?

|

|

|