I am having problems with wads blowing up into the hollow base of both my 12ga slugs. My slugs are the Lyman Forster and a Rapine 550/730. I've tried nitro cards and even an additional plastic gas seal under the slug, with no success. I often find the wads on the range collapsed, and even sometimes holes blown in the plastic gas seals. Grouping is terrible. But, if I fill the bases with hot melt glue, both slugs group fairly well. This tells me that this area is the fault. I can't procede with any load development until I get this issue resolved. Any suggestions from you slug loaders out there?

|

|

|

Reply With Quote

Reply With Quote

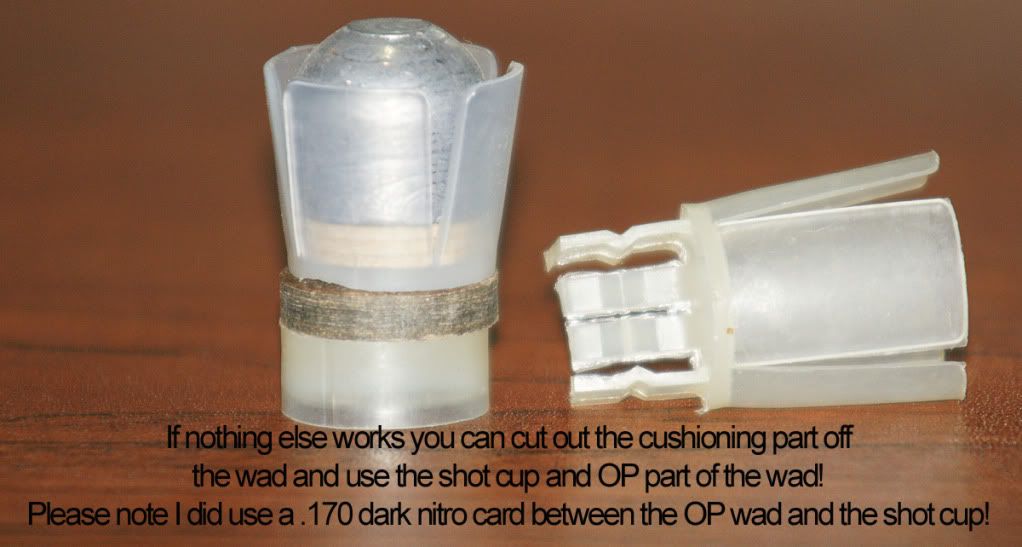

I would suggest not to use a forster slug in a wad cup or did you mean a 525 Lyman? I like to see wads look like this after firing 525's. The key for me is a slow burn powder so they don't get all that pressure all at once.

I would suggest not to use a forster slug in a wad cup or did you mean a 525 Lyman? I like to see wads look like this after firing 525's. The key for me is a slow burn powder so they don't get all that pressure all at once.