It is much clearer now.

Like strong coffee, compared to thick tar.

|

|

|

It is much clearer now.

Like strong coffee, compared to thick tar.

Woh been awhile since I've checked on this thread you guys are getting really technical. Ya the Zinc seems to dissolve the alum not melt it which is weird but it works.

No I don't have a chrono at this time but I really need to get one I would like to see how fast I can push these bullets I have been talking with Accurate Arms lately trying to find a safe max using something like AA#2. I'm thinking about getting a Lee 102gr mold to throw out some 50ish grain zinc/alum bullets.

Didn't have much zinc left but I did some playing in the shed today with it. (Yes I use propane, the side burner on my grill and a hand torch to be exact) Well instead of using Zamak 3 (zinc/alum) I thought I would try to make some out of Zamak 2 (Zinc/Alum/Copper) well the only problem I see with that is the melting temp of the copper but I found that if you take really thin copper wire it melts fairly easy so I alloyed some in with the Zinc/alum compound. Only cast about ten today but 80% of them turned out fine the other 20% the base was not prefect but they will shoot fine i'm sure. I would like to be able to test the hardness of these bullets as Zamak 3 has a brinell hardness around 100 and Zamak 2 should be closer to a brinell hardness of 130.

I use a Lee MOLD DC TL356-124-2R for the zinc rounds it is the same mold I use for my lead bullets I was wondering if I make the holes in the top of the sprue plate bigger will that have any negative side affects when casting lead bullets

Hi Thomson,

I have some questions for you.

Do you have a chronometer? Do you shoot this exact bullet in lead? Do you have a load using this lead bullet that groups well?

What I am very much interested in is the SPEED you shoot your cast lead bullet variant, compared to the SPEED you shoot the zinc variant.

In other words, what I want to know, is if you have two identical cartridges, same bullet cast from the same mold, same primer, same powder, same reloading process, same EVERYTHING but one bullet is lead and one is zinc, and when fired they come out of the barrel at the SAME SPEED (meaning the zinc round of course has less powder)

do they group the same?

----------------

For the engineers I can hear just straining to respond with the academic responses, I KNOW it shouldn't be the same, it shouldn't work, it's not that simple, it's comparing apples to oranges, I know!

............ But do they group the same?

Do you have a chronometer?( Nope I don't have a Chrono at this time) Do you shoot this exact bullet in lead?(Yes this is the same mold I use for my lead bullets) Do you have a load using this lead bullet that groups well?(Yes in lead 4.7 gr of unique with a OAL of 1.120 does good)

What I am very much interested in is the SPEED you shoot your cast lead bullet variant, compared to the SPEED you shoot the zinc variant.(Again I wish I knew but I don't have a chrono, but as of now it's 4.7 gr Vs 7.5 gr of unique.

In other words, what I want to know, is if you have two identical cartridges, same bullet cast from the same mold, same primer, same powder, same reloading process, same EVERYTHING but one bullet is lead and one is zinc, and when fired they come out of the barrel at the SAME SPEED (meaning the zinc round of course has less powder)

do they group the same?

(not a clue I have not done enough testing with the zinc rounds to know how they compare to the lead but so far they seem to be very accurate loading them as I am now)

Hope I answered some of your questions.

Have a peek here-----------------it may shed some light on your "alloy"----------Zamak alloys have been the diecast industry standard for years

I haven't gravity poured any but i have "disecast" (pressure injected) tons

http://www.eazall.com/diecastalloys.aspx

Dave

Be careful with melting Zinc/Aluminum alloys.. At higher temps, it will attack steel and iron vigorously.

When I was scrapping some Aluminum, I got some Zamak in the mix and it ate through a 3/4" cast iron elbow.

"Unnh, Negative. I am a meat popsicle."

Chuck

Ya I'm using an aluminum mold so I was worrying about the zinc attacking the mold itself but I have yet to have any problems with that probably because it is cooling down in the mold.

Talked to accurate arms about my Idea of using the 102gr mold and casting bullets around the 50gr range the load data they came up with using AA#2 is

Start load:6.0gr

Max load 6.6gr

I'm guessing that's using an OAL of 1.120 as I told them that's what I am using on the 80gr zinc rounds that I cast now.

I really have no reason or use for these I just think it would be neat to push a 50gr 9mm bullet in the 2400 fps range, probably could set tannerite off with it which would be neat as most handguns from what I read won't.

Another question I'm sure someone has tired reloading steel cases before I have yet to ever even shoot any but I was thinking shouldn't steel cases be stronger? If so couldn't you use steel cases to run higher pressures?

Last edited by Thompsoncustom; 02-28-2012 at 05:58 PM.

Interesting. My post from half a week ago got deleted. I wonder how that happened.

Thompson, I would be very very interested to know if the group size for your fast zincs are the same as your slow leads.

Well there's only one way to find out. Tho I won't be able to match the speed of the bullet unless someone has a way of doing it with out a chrono but I could see how the zinc do compared to the lead. I only shoot the Zinc from my C9 and the rest of my shooting is done from my CZ so I'm not the best with the Hi point but prone at 30 ft on some sandbags I think I can get it close enough to judge. Don't know if over time these rounds will damage a gun or not, and if anything where to go wrong this gun is build like a little tank and I think I would be fine. Funny that the C9 slide is made out of the same stuff the bullets are just not sure what Zamac #? they use.

I don't have a chrono either yet. The way I'd do it is just examining load data for the same, much lighter weight bullet, and using that as an indicator for how much power for how much speed. Maybe barnes bullets data, since they are so much harder than lead.

update:

Looks like my lee mold has succumb to the heat as one of the tumble lube grooves now sags. No big deal tho just tells me I was getting it to hot and lee molds are cheap enough luckily. So I order two new molds but the one I'll be using from the zinc round is the lee 102gr mold. I'm thinking I should be able to push these somewhere around 2000 fps and lube is not a problem as I have run them both ways and it doesn't make a difference, this is with me guessing the zinc bullet will drop at 45-50 grains .

Whiterabbit when I get this I think I will be able to test it against the lead round now that I have "quickload" I should be able to get a close fps on both the lead and the zinc rounds.

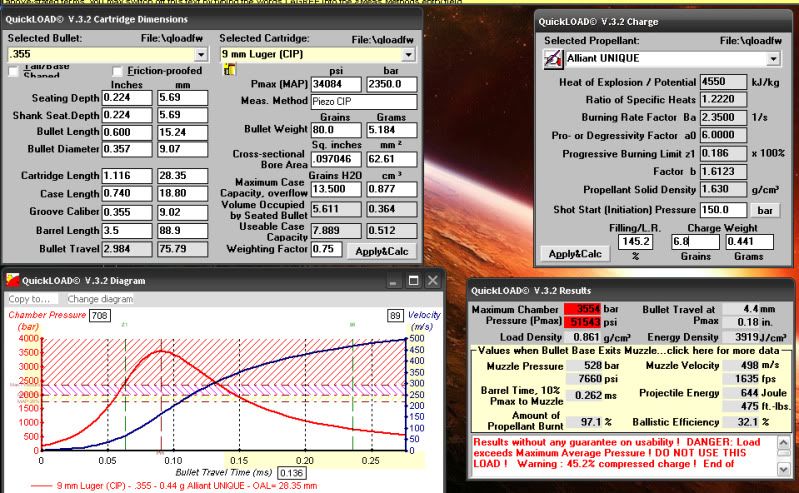

Have some questions with quickload tho, I measured everything on the current zinc rounds I was running and run it through quickload and this is what is came up with.

I assumed that with 7.0gr of unique there was a lot of powder not being burnt but the program says most of it was and that the bullet was traveling just over 1600 fps. Anyone see any errors I might have maybe using this program as it is still very new to me.

Anyone have specs on the lee 102gr bullet? I would like to run it through the program and see what I get but I need the bullet specs. Otherwise I should have the mold next week and can do it then.

Well I don't have a chrono but I think I reached over 2000fps with these 55gr bullets for the first time today. After running it through quickload I found that it should take 8.2gr of AA#2 to get over the mark and the pressure level was in the 50k area so I set up a wood vise and a long string and shot these bullets at the side of my 1/4in steel bullet trap. I loaded up 2-7.8gr 2-8.0 and 2-8.2 and man do these things hit hard tho they did not make it through the 1/4in steel the 8.2 came very very close wish I would have had the camera with me today.

bump.

"If you have a nick-nack with a nick in it we'll knock the nick out of your nack with Brighto!" -Larry Fine

Casting on dry land...

A lot of metals melt at lower temperatures when mixed in an alloy than they do when melted alone.

Zinc bullets do not need lubrication.

There is no reason they should harm the bore. They are not that hard and not abrasive. After all people fire copper and bronze bullets okay.

I wonder how these perform in a pistol caliber carbine...

My CX-4 spits out lead at about 1450 fps, I wonder if a flatter trajectory at much higher speeds can be obtained...

Which has me wondering, can powders that might be better suited for rifles be used in pistol caliber carbines? (Different rate of expansion maybe?)

I believe you...but my Tommy gun don't.

I have a few questions and a comment on Quickload.

The first thing I noticed with you screen dump of Quickload is that you are likely getting faulty data from it because you have one setting off. The start pressure of 150 bar is quite possibly too low because the zinc bullets are less easily deformed to the rifling. I'd be EXTREMELY careful about trusting the peak pressure figures! By using the more correct (I wouldn't really trust this completely either) start pressure of 449.9 BAR, your pressure is more like 60,029 PSI...WAY too high for a hand gun!!!!!!!!!!!!!!!! I am concerned about the un-seen damage you could be doing to the firearm. I'd guess (and it is just that) a FMJ with a steel core would more closely approximate your start pressure.

Quick load has the boolit data for the Lee .356-102-1R. I used that boolit description, but changed the weight to 80 grains.

Also I'd guess you are getting every bit of energy out of the Unique because of the extreme pressure you are like generating.

I assume you're using a ladel to pour the zinc...is that correct? Are you using any lube? Did you actually weigh the cast bullets?

Remember Quickload is a tool, but if you have any data input incorrectly, the output WILL be flawed. Garbage in, garbage out. Use the programs as a reference, not as Gospel!!!!

Edd

Last edited by badgeredd; 01-15-2013 at 11:49 AM.

Charter member Michigan liars club!

"The strongest reason for the people to retain the right to keep and bear arms is, as a last resort, to protect themselves against tyranny in Government." -- Thomas Jefferson

"Consider the clown(s) just one of God's little nettles in the woods, don't let it detract from the beauty. Sooner or latter you are going to run into the nettles regardless of how careful you are."

Beware of man who types much, but says nothing.

Hm. I'd think that powder choice would be an important factor to consider. A cast bullet made from Zinc, since it is lighter, should exit the barrel faster than a lead bullet cast from the same mold. Right? So knowing that, what would be the best kind of powder to use? Fast expanding?

I believe you...but my Tommy gun don't.

I tried that zinc thing. Didn't work out so well for me. About a thousand rounds down the barrel of my 29 with full house .44 mags saw it being boxed up and sent to S&W for a new tube.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |