You can run a DC motor, and power it with an adjustable DC source. The less DC amperage the slower it turns.

|

|

|

You can run a DC motor, and power it with an adjustable DC source. The less DC amperage the slower it turns.

Here's a simple inexpensive control:

http://www.ebay.com/itm/30A-DC-PWM-M...#ht_2301wt_802

Of course it does come with chop stix so have your rice ready.

Actually scratch the rice burner. I don't know what I was thinking.

Ebay "KB Control". You can get a heavy duty USA made control to run various inexpensive industrial DC motors 90-120 volts with a KB for under $50.

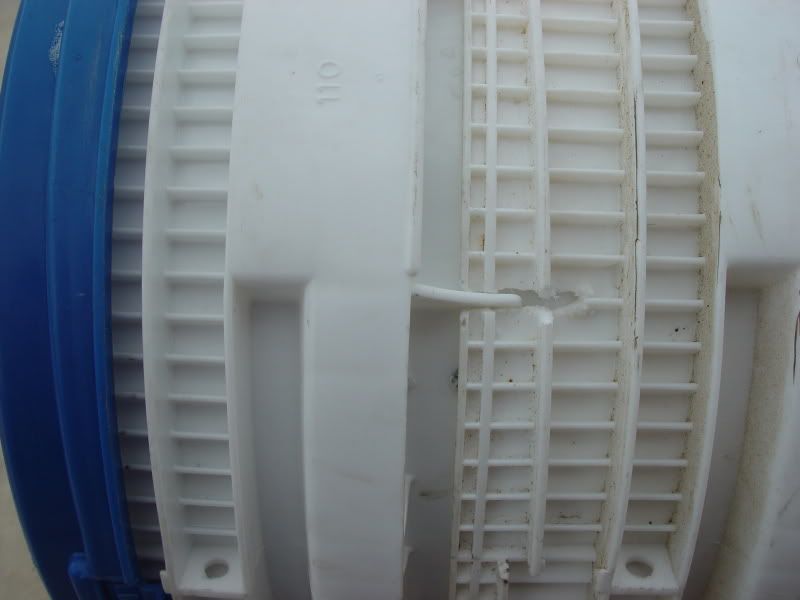

Did you find the slotting was actually necessary for the bucket in a bucket drive system?

Seems like they would stick just by friction fit. ???

(But then, I haven't stacked two chlorine buckets to see if they stick like others do.)

God Bless America!

Sittin here watchin the world go round and round...

Much like a turd in a flushing toilet.

Shoot for the eyes.

If they are crawlin away, shoot for the key hole.

NRA Life Member

CRPA Life Member

Magnificent!

The basic flaw with Science is man.

jmorris: wondering if you could tell us what shot you got from Pellets LLC? The picture doesn't have spec detail on it.Originally Posted by jmorris

Do you guys prewash your brass, or just drop it in the tumbler? No follow up in a vibrator needed?

Thanks! Phil

If you guys need low speed gear motors you can sometimes find decent pricing at surplus center

www.surpluscenter.com

look in the gear motor section, they have both ac and dc motors

I had to slot the bucket to get them to "snug" up to one another. I asked the sales person at pellets inc for the "brass casing size" it's .248" long and .039 by a caliper but I didn't get out a mic. I didn't pre wash any brass but do rinse it off after. Surplus Center has some pretty good deals but nothing like ebay, if you take your time and don't get caught up in bidding and watch shipping.

PMN: just ask the guy at Pellets LLC for SS brass cleaning media. He will know what you need.

The pins are actually .041 in dia x .2 ish long.

Randy

"It's not how well you do what you know how to do,,,It's how well you do what you DON'T know how to do!"

www.buchananprecisionmachine.com

That is an awesome beefy monster! My hat is off to you.

However, I did buy a new 40lb tumbler marketed on fleabay for around $275. Not bad for those of us without Jmorris's mechanical/engineering skills.

jmorris:

Back to the pictures of the bucket being assembled, please -

"I then cut 4 ribs 1 5/8” tall out of ½” thick plastic and bolted them in to the inner bucket, using 10-32 counter sink bolts, every 90 degrees to agitate the brass and media."

I'm curious about how you waterproofed the bolt holes against leakage. I can't find any products that stick to the HDPE-2 that the buckets are molded from.

Help a guy out?

Thanks.

I was going to use a product called E6000. Its an adhesive sealant that I have always been impressed with, even on glass to glass.

However, after my first trial without using anything there was no liquid in the inner bucket. So until it starts leaking, I am just using the counter sunk screw head to seal it shut.

Neoprene washers with fender washers slightly bent to fit.

This tumbler sure is "kiss" engineered.

Don't recall where I found it.

Could have been here.

Last edited by Longwood; 02-04-2012 at 07:40 PM.

jmorris & Longwood:

Thanks for the reply's and info.

I've got 2 paddles in a 5 gallon bucket. I used a few different sealers (silicone types, caulk types) with about 80% success so far.

I'm going to try rubber washers between the bucket and the paddle with a dab of silicone in the hole before I thread the fastener through.

I got my Gamma Lids to leak a lot less through the screw on seal by whacking the cross-ribs on the lid with a rubber mallet in a CCW direction to spin the lid about 10* tighter.

I'm losing about a cup of water/30 minutes so far, and I'm hoping it doesn't get worse.

I don't think I'll ever have 100lbs in a bucket. I have been gathering parts and currently have a Bodine DC gear reduction motor and a Bodine 815 speed controller. Its .87-42 rpms. I was planning on using a 3/4" shaft and two pillow block bearings for support. Once thru the 3/4" ID bearings it will go to a lovejoy 3/4 to 1/2" coupler.

With the two pillow block bearings to take the load do I need anything under the bucket for support in your opinion?

That one is still going without anything supporting the bucket. I guess it depends on your bucket, the ones I used are stouter than your homedepot/lowes 5 gallon bucket (on right).

I keep looking at the HF cement mixers and thinking they would work.........1 1/4 cubic feet and 3 cubic feet, a 35 rpm motor, stand and tilter to dump the contents.......around the same price.....good looking work!!

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |