I had a set of Lyman 30 -06 dies, the seating stem made " a ring " on the nose of my 311291 bullets. While probably not serious enough to have much affect on accuracy ( or anything else ), I still found it objectionable.

The remedy was to do the same thing that I do to Lyman top punches that fit poorly ..............Use slow curing JB Weld.

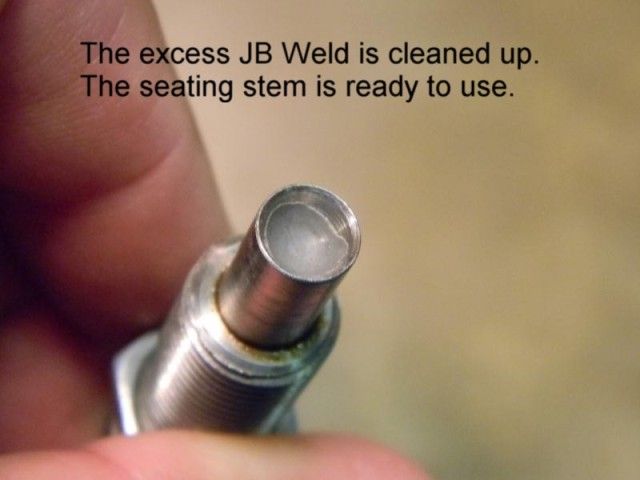

I coat the nose with a coat of Brownell's Acra-Glass release agent, degrease the inside of the seating stem with Brake Cleaner, fill the nose of the seating stem with JB Weld, fit the two together and align them properly and put them in compression for 24 hrs.

Many of you have heard of this, some may have not seen it, so I thought I'd post the " before and after " of this project.

Ben

|

|

|

Reply With Quote

Reply With Quote