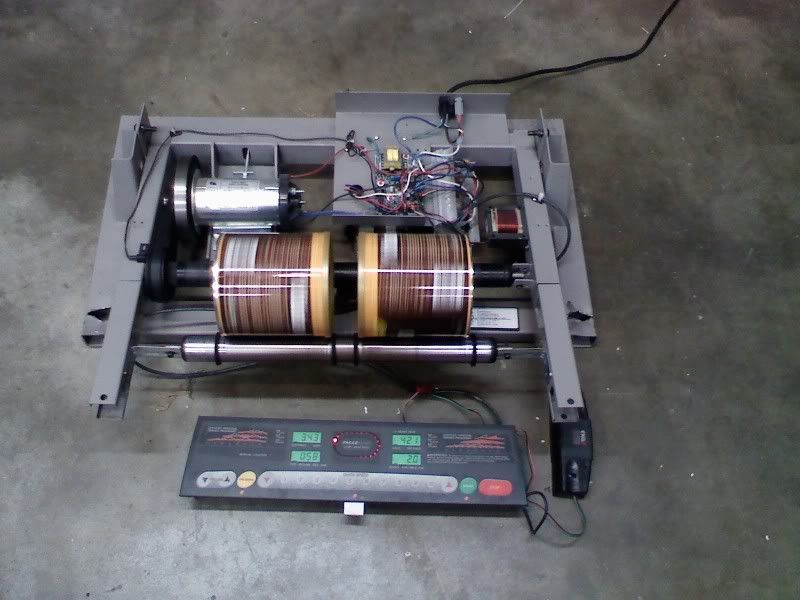

I'm trying to make a rotory tumbler.

I have a motor from a Bosch washing machine.

Can't find the wiring diagram.

Someone know anything about these motors????

There are 5 blue wires and one white wire in a gang plug.

The white wire is a grounding wire.

It looks like two of the blue wires from the gang plug attach to, what looks like, a speed sensor on the rear of the motor.

The other three go into the motor body.

This was a 110v washing machine.

I think if I can get this motor to work, it would make a great tumbler motor.

|

|

|

Reply With Quote

Reply With Quote