I was reading the Lyman's Cast Bullet Handbook, 4th edition. One of the authors talks about only keeping bullets that fall within .6 grams of each other. Six Tenths of a grain. I was surprised at that number so I went to the "lab" and did some weighing.

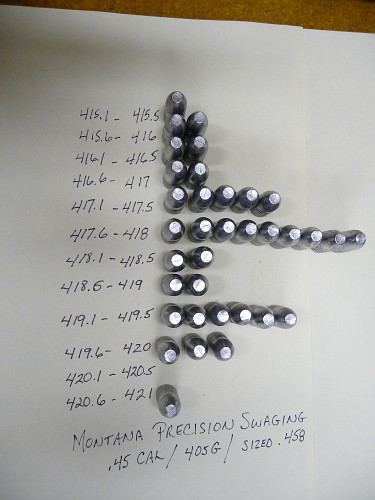

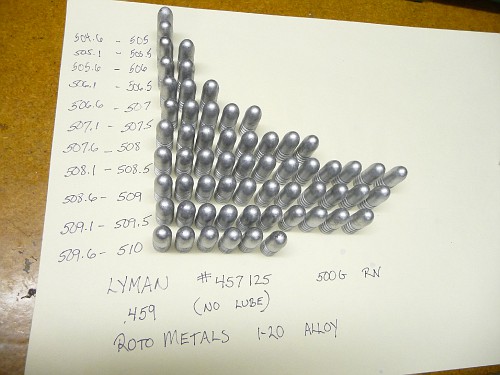

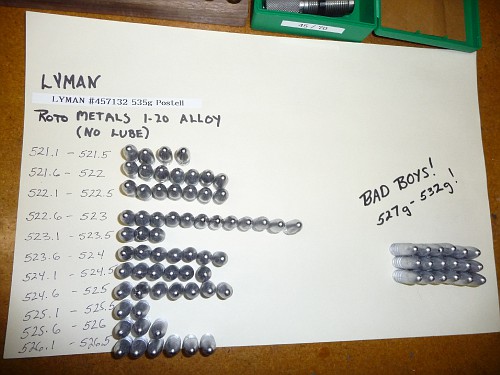

I used the same technic as spelled out in the handbook of making a visual chart to log the various weights.

First up are some lubed bullets cast from Wheel Weights.......

The next group was from "manufactured" bullets that I had bought before I started casting myself.....

And another series of "manufactured" bullets....

This group is from bullets I cast yesterday. Not lubed yet.....

And finally a very surprising outcome. What's up with those Bad Boy bullets????

Comments? Anyone else ever weigh their boolits and see how consistant they are?

I'm going to keep accurate records as I shoot these boolits to see how this affects accuracy.........

|

|

|

Reply With Quote

Reply With Quote