I have found that boolit bases are peened and cupped with high loadings of slower powders just like DrB has predicted!This also gets me to wondering about the folks who have reported shooting unlubed bullets with a cream of wheat filler. If this theory is true, I suspect that you might be able to do the same thing with a slow burning charge of powder.

I'll need to check but I seem to think that with higher load densities and only a small amount of wheat bran, the base peening and cupping is less than without. It is hard to assess due to the damage sustained by the boolit on impact in soft sand. I'd have to use damp rags as a catch medium to see for sure.

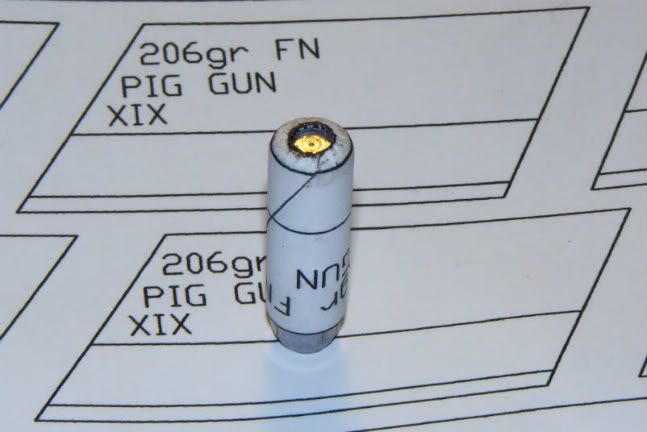

Rebate base showing cupping.

Strong cupping with pronounced edge rim.

All my photo's seem to support DrB's hypothesis.

|

|

|

Reply With Quote

Reply With Quote