Is this lathe big enough for gunsmithing work?

http://www.grizzly.com/products/10-x...al-Lathe/G0602

|

|

|

Is this lathe big enough for gunsmithing work?

http://www.grizzly.com/products/10-x...al-Lathe/G0602

NRA Life Member

"The Constitution preserves the advantage of being armed that Americans possess over the people of almost every other nation, where the Governments are afraid to trust their people with arms." - James Madison.

...........chrisx1, It could certainly do 'some' gunsmithing work. With that 1" spindle bore you could pass the muzzle end of a barrel through it and run the breech end in the steady for chambering. You'd have to make a spider for the tail of the spindle to carry the barrel. All that would depend on the taper of the barrel of course, as to how much room you'd have left over the bed to work with. The only actions you could set up would have to be smaller then 1" in OD.

The main complaint I have with these smaller import lathes is their lowest spindle speed is rather high. Threading up to a shoulder routinely with the spindle running that fast would eventually give me hivesThey don't say anything about a backgear and if it had one I'd think they'd say.

It has all your basic stuff with it so you'd be set up for most initial lathe work. Most folks getting a new lathe spend the first few months modifying it and making stuff for it. Just do a web search on "7 inch lathes" or "7x10, and "9x20" and you'll see pretty much the same type of stuff being done. That Grizzly G0602 appears to be an upsized 9x20 machine.

I'll bet the motor is on the backside, at the bottom of the headstock. If so the hot setup would be to adapt a DC treadmill motor and then alter the gear train to offer a slower speed. With the DC motor you'd also be able to reverse the spindle rotation which would be handy, even with the threaded spindle nose.

Check out this site: http://www.bedair.org/9x20camlock/9x20project.html I think you'll find many similarities between the 9x20 and that 10x22.

...............Buckshot

Father Grand Caster watches over you my brother. Go now and pour yourself a hot one. May the Sacred Silver Stream be with you always

Proud former Shooters.Com Cast Bullet alumnus and plank owner.

"The Republic can survive a Barack Obama, who is, after all, merely a fool. It is less likely to survive a multitude of fools such as those who made him their president."

Shrink the State End the Fed Balance the budget Make a profit Leave an inheritance

Yes it can be used but you will never be really satisfied. I never owned any more than an Atlas. I could do almost anything but it took longer and less accurate (Deer rifle - no problem, varmint rifle - border line, bench gun - no way)

Chrisx1;

Gee, ….. While I will admit that Grizzly brings in some of the better Chinese imports, I have to give you what the pilots call a “Wave Off”.

I was in your position a couple of years ago. I looked at the imports, and never felt completely comfortable with any of the lathes that were in my price range.

After a couple months of prowling Ebay, …I ended up buying a 40 year old 12” Logan for $500. It is the nicest piece of machinery I have ever personally owned. It has a 1.375 clear bore through the spindle, runs “glass smooth”, and all the hand wheels turn like micrometers.

The good, old “American Iron” is still definitely out there, and many pieces are incredible bargains.

If you buy an import, based on retail pricepoint, I guarantee that you will be shopping for a lathe again in five or ten years.

If you buy a older piece of American machinery that is in good condition, your grandkids will be using it! ….And most probably still be able to find parts for it!! (Try that with a 25 year old “Rong Fu”!!)

Kent

KLC

“.....Nuttier than a squirrel turd.” - An assertion by a fellow forum member

i have to agree with klcarrol on this. new machines in that price range leave alot to be desired in all aspects. used american iron is good but you also have to be careful about buying something worn out and needing rebuilding. if you shop used american it is a good idea to have someone knowledgeable go with you. another thing to consider is if you have the budget for a $1K machine now, if you wait another year could you come up with another $1K? this would give you time to look for a good used machine or $2K to buy a much better new import.

The real problem with the asian imports is replacement parts!

Everything is done as a "cottage" industry so it's rare to get spare parts!

My freiend "Chip" had a Haerbor Freight lathe, and mill, for many years and we did some seriuos work with them.

However the day came when a loud "ka-thunk" came fromt the headstock area of the lathe! The bearing race had broken in two and, you guessed it, HB suggested buying a new lathe cause parts were "like never gonna happen dude"!

Fortunately Chip worked at a facility with a full on machine shop doing in house maint. and an old school machinist that kept things going as a "hobby". The old boy took one look at the race and had one ready in two days! He actually enjoyed having the challange!

So if your not fortunate enough to have those kind of "bennie's" with friends or family I will also suggest a higher end lathe or a stout American piece!

Here in L.A. I can find Logans, Atlas, Southbends and a few lesser known brands and I've seen them run the complete price range from 500 to 2500 but in the end each and everyone of them was worth the asking price.

As an example a place in Sante Fe Springs had an Original Sears / Atlas 9 inch lathe from the 60's on display / sale. They were asking $2500 for it 3 years ago. You might think this a bit high for a 36 inch baed machine BUT it was unused and had every option Sears ever offered for this machine including a rotating tail stock with tooling in it!

Had I had the cash it would have come home!

Deals can be found! Save the money and let your fingers do the walking on the web!

............chrisx1, Well I'll re-post. First old American iron can be a gamble. You have to know what to look for, and what to pay attention to. Most importantly is the ability to see and hear it run. It can have a new coat of paint on it an look all shiny but it still may be a turd under it all. The issue of parts was mentioned. Logan's are still pretty well supported by Logan Actuator which is owned by Scott Logan, the grandson of the original manufacturer. Logan made about 90,000 lathes, so you'll find some used stuff around. Seems like stuff for the 10" machines abounds. South Bend is "America's Lathe" and God only knows how many lathes they built.

I believe they're still supported by Clausing I think, and used parts are common. Clausing is another good lathe and usually heavier then Logans or SB's, but nowhere near as common. Rockwell made an exellent lathe but parts are made out of Unobtanium. Sheldon is another outfit that made home shop useable lathes but parts are rather scarce. Name any number of former American made machines and any in depth new parts inventory is almost laughable.

I was very lucky buying my lathe as I bought it from a friend (who is a member here). He was some kind of middle management guy with Pacific Bell who ran commercial telephone installation crews in the Southern California area, which included several commercial zones. As he was interested in machining he spent much unsupervised time hanging around machine shops in the Santa Fe Springs area. Norwalk blvd was solid machine shops up and down both sides of the street with many involved in defense stuff. This was in the 1980's to mid 90's.

With the demise of the Evil Empire and subsequent gutting of the armed forces almost all these placed folded. Since a still viable compnay could not afford to buy used equipment, (and this was way before E-Bay) he said in many places the owners just walked out and left everything or called the scrap guy to "Come and get it". He had an older Logan 11x36 machine he'd aquired before and was using. He'd gotten mine from a place that had used it for turning plactics of some kind, but had shoved it up against a wall. The shop owner said it'd been sitting for 4-5 years.

My Logan was actually made by Powermatic who bought the Logan lathe company in 1970. My 11x36 machine was made in 1981, so for it's size it's a rather recent one. It had had it's carriage, leadscrew, QC box, and tailstock removed. It was used with a bed mounted turret and a cross bed dual toolpost setup so the bed was essencially like new. When my friend bought it he had to put all the stuff back on it, and they were basically new too. The bed is flame hardened, it's a variable speed underdrive and sports a 1-3/8" spindle bore and a L00 spindle nose.

I paid $1500 for it. It has a 2 hp Leeson 220v 3 ph reversing motor. Along with the lathe I got the 8" throw bed turret, dual toolpost crossbed feed, a Buck 6 jaw Adjust -Tru chuck, a Buck 2 jaw Adjust-Tru chuck, a 3 jaw Rohm chuck, and a 4 jaw independant Pratt Burnerd chuck, so I was fixed for chucks. Then it had a 5C collet closer and spindle adapter installed. Along with all that he threw in a couple face plates a 'T' slotted face plate, two dog driver plates and a box full of lahe dogs, dead centers, bits, gibbs for who knows what and other junk. SInce it was all for L00 spindles it was useless to him, as his spindlenose was threaded.

Since just the 6 jaw Buck currently sells new (mine is used) for about $1400 I paid for the chuck and all the rest was freeThis was a VERY, VERY uncommon deal to be sure. Most all the stuff he got for free as it was all being tossed in dumpsters. He said he'd go home at night with the trunk of his Taurus dragging the ground. The man STILL has chucks and junk in piles

The fact of the matter is that ALL import (read: Asian) lathes are not junk. That means some are. Some retailers take whatever comes down the line. Grizzley actually has their own final imspectors in place who check out and give the final okay on the machines they sell. The machines HAVE to meet specs, and their production is watched up and down the line. It does seem however that Chinese motors are invariably a joke. You can pay one price for a machine with a Chinese motor, or for a bit more an American motor.

An oddity too is that some milling machines have the body, knee, and table produced in China, but hurrah the fact that the head was made in Taiwan. The Chinese are not idiots and they can build machines to most any level of competance the customer wants to pay for. My 9x42 vertical mill I bought from ENCO carries a 1 year warranty. The knee, and table in both X & Y traverse are as smooth as greased snot. Put a dial indicator on the table and it won't flicker for it's entire travel.

My suggestion is to determine exactly what you want to do with the lathe so far as gun or other hobby stuff might be. Fantisize as to what you'd REALLY like to have. Look at what you can afford now, and then think about what you might be able to swing next year. As one poster suggested. Might be worthwhile to wait? I waited 3 years to get the mill I wanted as I knew I wouldn't be satisfied with anything smaller or less capable, and would ALWAYS regret spending the seed money that could have financed something much closer to my fantasy, just a bit later.

.................Buckshot

Father Grand Caster watches over you my brother. Go now and pour yourself a hot one. May the Sacred Silver Stream be with you always

Proud former Shooters.Com Cast Bullet alumnus and plank owner.

"The Republic can survive a Barack Obama, who is, after all, merely a fool. It is less likely to survive a multitude of fools such as those who made him their president."

Shrink the State End the Fed Balance the budget Make a profit Leave an inheritance

I have a 9x49'' knee mill I bought from Grizzly because they offer replacement parts. Nice machine backlash on X & Y axes needed to be adjusted but has been fine for what I do.It is as good as the Jet or Rockford I had before this one.

I have a Victor 14x40B lathe that I bought to replace barrels on Remington 700s and Mauser rifles and also true the actions. The first Mauser barrel I did was on my Pratt & Whitney Model B that was a 12x30'' and it was real tight working all the way on the end of the bed and the spindle was way too long to fit a spider on the outboard end. I also had a Southbend 12x36 G-26T toolroom lathe that would have been suitable for barrel work but I never got a chance to use it very much, That is a nice size and there plenty available by different manufacturers.

The problem with most smaller lathes especially the cheap ones is that they use the lead screw for both power feed and threading causing premature wear and inaccuracy when threading,look for a separate lead screw and feed shaft and a quick change gear box.

Visit "The Homeshop Machinist" site and read up on lathes and machining before you take the plunge,once you pay full retail for a lathe you find you don't like you can only lose money on it, a good buy on a used lathe and you may be able to make money on it.

My Pratt & Whitney was a graduation present from my machinist teacher and had been used in the trade school . It was made in the 1940's and was a little worn close to the chuck but a good machinist can do good work on a worn machine,it just takes a little longer. The first shop I worked in only had worn out machines and we were able to make .0005'' bearing fits on those raggedy machines.The Clausing Colechesters we used in school had taper in them also, took me 3 days to make a 1'' shaft for my first Southbend step pulley.

Also look in to your local community college to see if they offer machinist classes.

Last edited by deltaenterprizes; 12-31-2008 at 11:10 AM.

Parts and tooling for the small Chinese lathes and mills can be obtained from Little Machine Shop.

http://www.grizzly.com/products/12-x...ed-Lathe/G4003

I bought that lathe right there and I have been very happy with it so far. In the future I will put a 3 phase motor on it and run it with a VFD for a slower "low" speed. One issue with some of the smaller grizz lathes is they ONLY feed and thread right to left, and that is a handicap I am not willing to accept.

The 12x36 is really pushing it to chamber a barrel without putting it up through the head stock, the headstock is right around 20" long so most barrels will work in the headstock, and anything shorter will work with the steady rest.

I like old iron, but as others have said it has issues of it's own, one being the complete unavailability of new spindle bearings in many cases, and if they WERE available they would be a $3000 pair of bearings probably. Also the headstocks are typically too long to allow shoving a barrel thru the headstock...no real handicap there I guess as I prefer the steadyrest method myself.

The lathe at the link above takes off .001 when you tell it to and turns nice and straight right out of the box, I got my $2300 worth I think.

Oh hey, also..........the turning tools they give you with that lathe all things considered are a hands down WINNER...they work quite nice for a tool that uses a $2.125 insert that has 3 corners to use, the threading tool/inserts are a no go because the insert has too large a nose radius.

Bill

Both ends WHAT a player

I just regrind one side to get rid of the radius.

...........When I got my lathe home (I'd previously ordered the Logan Manual for it) I was fooling around with it and discovered someone had been into the headstock. The 4 belleville pre-load washers around the left end of the spindle were nested (no compression) instead of opposed in pairs. Since I didn't know (nor did my friend) who, when or why someone had been futzing around in the headstock I figured I'd go ahead and replace the bearings.

The Logan book showed 2 bearings carrying the spindle. A double row opposed bearing in front and a single row on the outboard end. Pulling the spindle had TWO single row radial contact bearings on the nose end and the single row outboard. I called Scott at Logan and he was aplogetic. On the Powermatic version of the 11" lathe with the L00 spindle nose they'd gone to 2 bearings.

I went to the bearing house with the bearing numbers and the bill came to about $180 for the 3. I asked what ABEC rating they carried. The gal looked at me like I'd just grown another nose! She said, "These are electric motor grade bearings". I was a bit dismayed. She asked me what they were going to be used on and when I told her she said that these bearings wil be just fine. Just for fun I asked her what a set of ABEC 5's would cost for the 2 front bearings.

She looked in her books and said that they'd be about $350 apiece, and there could be a couple weeks wait to get them in. I think I swallowed my tongue. She smiled and said, "Trust me, those bearings will be just fine". I decided they'd probably be just fine too, and they have been. The original Logan specs was that the spindle could not be off axis more then .0005" at 12" from the spindle nose.

During WW2 there were many things the government wanted made and spec'd that the lathe's used had to be plain bearing machines eg: split babbitt or cast iron bearings (bushings) to carry the spindle. Ball bearing technology before then just wasn't what it was to become, nor what it is now by a long shot.

................Buckshot

Father Grand Caster watches over you my brother. Go now and pour yourself a hot one. May the Sacred Silver Stream be with you always

Proud former Shooters.Com Cast Bullet alumnus and plank owner.

"The Republic can survive a Barack Obama, who is, after all, merely a fool. It is less likely to survive a multitude of fools such as those who made him their president."

Shrink the State End the Fed Balance the budget Make a profit Leave an inheritance

I'm not a very accomplished machinist, but do have two lathes, a 10x36 Craftsman (Atlas) and an 8x10 Cummings Tools Chinese mini lathe. I only bought the Chinese lathe 'cuz I got a killer price on it off of Craigslist, but in truth hardly ever use it. My Craftsman does everything I need it to, even on small pieces.

I think Clausing still sells the Atlas/Craftsman parts, but I've found everything I needed off of eBay over the years.

BTW, I paid $400 for mine and it came as a box of parts. I bought it from a friend who swore everything was there. He had a couple of identical extra lathes and gave the assurance that I could have needed parts from one of his other machines if anything was missing. In fact, every nut and washer was in that box and it was a pretty good education to build it from the ground up.

I have to manually change gears to cut threads, but that's not too much work and I don't do it often enough to consider it an inconvenience.

I like my Craftsman and since I'm not building Space Shuttles, it seems more than adequate for anything I've tried to tackle.

Best regards

Doc

Hi,

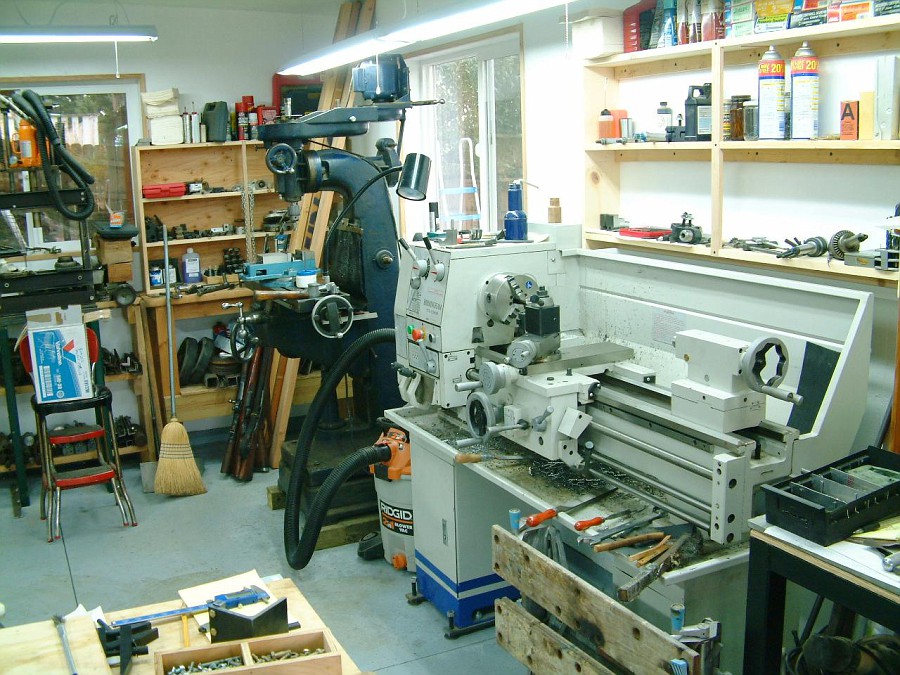

I thought I would try to post some pics to show a more or less basic deal you run into with american iron. This is a 1945 12X36 Clausing 100 MK3A lathe. I paid $1500 which I still think was a little high but it is in excellent running condition and was available and I had looked forever and could not find anything better. Now with 20-20 hindsight I'm glad I got it. I bought it from a friend of mine who is a REAL Gunsmith (real being someone that gunsmiths to pay their bills!) He obtained a SB 16"X5ft model and could not afford both. Some gunsmithing lathe instruction was thrown in and I bought it. The good news is that it is a quality lathe that will do everything I need. Older Clausings are actually a little beefier than their SB counter parts and the lathe has Timken roller bearings in the headstock. The downside is unlike the SB there are not a lot of spare parts laying around! Howerever its so well made that if you run the machine correctly there is little to go wrong.

I have replaced the old wore out three jaw with a nice Chi-Com model along with a QCTP that has improved the quality of work very much and the best money I have put into the lathe! Something to think about as far as price is how hard is it to find machinery in your area? For myself being in central Fla. there is not the old machine shops and industry like say up north. Here Gold is where you find it!

http://castboolits.gunloads.com/atta...1&d=1231017883

http://castboolits.gunloads.com/atta...1&d=1231017213

http://castboolits.gunloads.com/atta...1&d=1231016576

Last edited by seagiant; 04-29-2011 at 06:07 PM.

I bought a 9x20 Enco less than a year ago to use on small stuff. I have a Jet 13x40 made in the mid 90's and its alittle big for somethings. I guess you get what you pay for but the 9x20 is not of much use to me. I would like to find one of the older 1980's mode enco 9x20, there were very good machines. If i were buying a new lathe today and just going to have one I would get something like the Grizzley 12x36. It has almost a 2" spindle hole. The Enco 9x20 won't cut or thread away from the chuck and the speeds are too high and feed too fast. riceone

I bought this machine last December and love it! But then again, it is my first machine! I never intended for gunsmithing, but have toyed the idea now for cutting down some barrels and small stuff.

I went with a new Grizzly because there just isn't a decent market here where i live for used American machines...

I added a quick change tool post first thing.

The lowest speed is rather high compared to others and there is no back gearing or reversing of the feed.

But i like it so far for my learning and tinkering!

Visit my projects at: http://cheese1566gunsandstuff.shutterfly.com/

Y'all might just be plumb amazed what is on eVil bAy as regards machine tools. Shaper anyone?

We need somebody/something to keep the government (cops and bureaucrats too) HONEST (by non government oversight).

Every "freedom" (latitude) given to government is a loophole in the rule of law. Every loophole in the rule of law is another hole in our freedom. When they even obey the law that is. Too often government seems to feel itself above the law.

We forgot to take out the trash in 2012, but 2016 was a charm! YESSS!

I started off with a small machine and was very disappointed in a short time. Best to save a little more money and buy this http://www.grizzly.com/products/Guns...h-Stand/G4003G. That 40MM bore comes out to 1&9/16" on the spindle, my biggest lathe is 1.5". I have four import machines ( three lathes and one mill) and have had very little trouble. Grizzly should be able to get any parts you might need.

Birmingham 12x36 gear head. Same as Grizzly G4003. I paid $2,000 + $300 freight in 2005. I think they're now $2,300. Been very pleased with it. Capable of sub .001" accuracy all day long. I've owned Von Wyck 15x60, Clausing 6300, Atlas 10x36". The Atlas is a good lathe, though a light duty lathe. Capable of excellent accuracy. I had 3C collet set up. The Clausing 6300 was an outstanding lathe. Capable of aerospace accuracy. The Birmingham is very much like the Clausing 6300.

The Dutch philosophy: A lathe is a serious piece of machinery that you will use FOR THE REST OF YOUR LIFE. I received an excellent piece of advise from a now deceased friend: Beg, borrow or steal $$$ to get that lathe. He was referring to the $500 for the 1903 Von Wyck 8 foot long monster at the time. If you have a spousal unit and DNA clones they can go a few more months with those worn out shoes and they can eat oat meal and day old bread a couple more months so DAD can save some $$$ for a bigger lathe. I would say the 12x lathes are outstanding for a home shop.

I sold $3,000 worth of guns <gasp!> to buy the Birmingham lathe. And I sold $3,000 worth of handguns to buy the Enco 1525 vertical mill (used) in 2009.

I traded a pistol for my lathe..a Montgomery Wards labeled Logan. I've really enjoy when I get to use it.

| BP | Bronze Point | IMR | Improved Military Rifle | PTD | Pointed |

| BR | Bench Rest | M | Magnum | RN | Round Nose |

| BT | Boat Tail | PL | Power-Lokt | SP | Soft Point |

| C | Compressed Charge | PR | Primer | SPCL | Soft Point "Core-Lokt" |

| HP | Hollow Point | PSPCL | Pointed Soft Point "Core Lokt" | C.O.L. | Cartridge Overall Length |

| PSP | Pointed Soft Point | Spz | Spitzer Point | SBT | Spitzer Boat Tail |

| LRN | Lead Round Nose | LWC | Lead Wad Cutter | LSWC | Lead Semi Wad Cutter |

| GC | Gas Check |