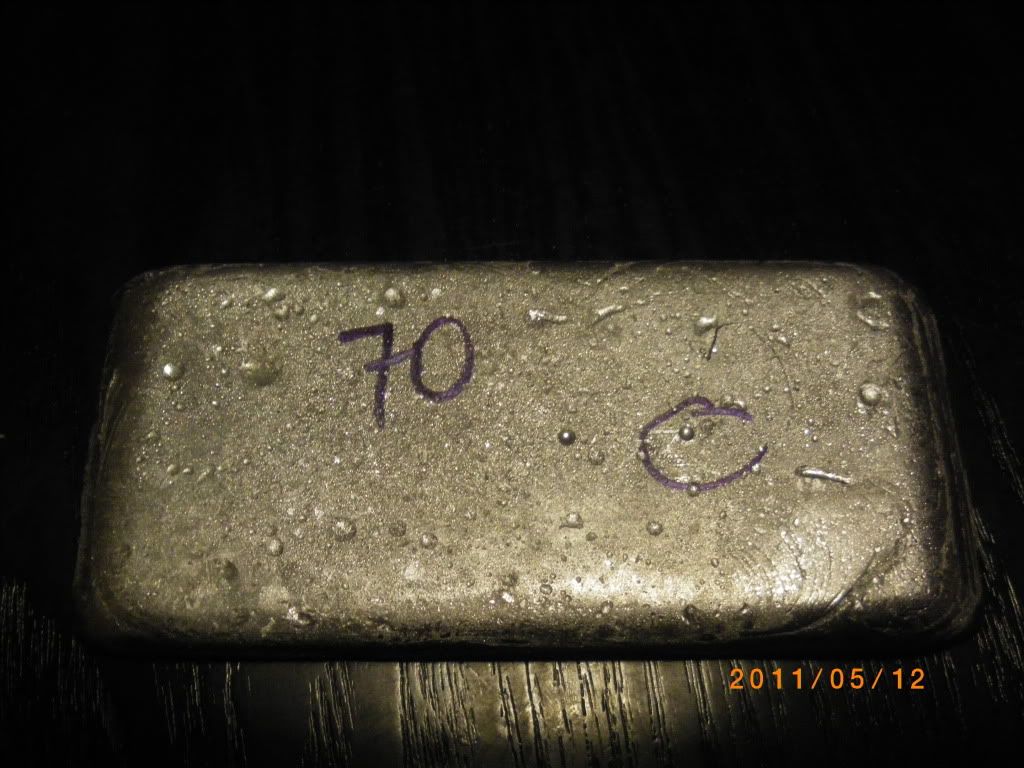

Hi Boolit dudes, can you guys help me out with using wheel weights to make boolits. So far l have melted down some clip on WW in an old aluminium sausepan and made some ingots.

l must say the end product looks like sh1t and when tested with a Lee hardness tester could only manage around 8BRN.

l thought WW were supposed to be around 11-12 BRN

Any hints or tips would be very handy .

thanks John

|

|

|

Reply With Quote

Reply With Quote

Casting, Reloading & Shooting

Casting, Reloading & Shooting