I'm new to PP. I have a good supply of Lee .309 180 gr. bullets gas checked and sized to .309" on hand that I want to PP for my P-14 rifle in .303 British. I am using 2 wraps of notebook paper and then sizing to .311" (Lee sizer die) About half of them come out with the gas check showing (paper being cut between the gas check and the sizer I am guessing).

In general, what performance difference would you get with the gas check exposed? Any problems to look out for? Should it perform like I regular PP bullet?

Thanks,

|

|

|

Reply With Quote

Reply With Quote

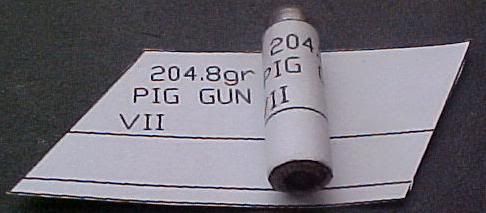

Kills turkey's dead!

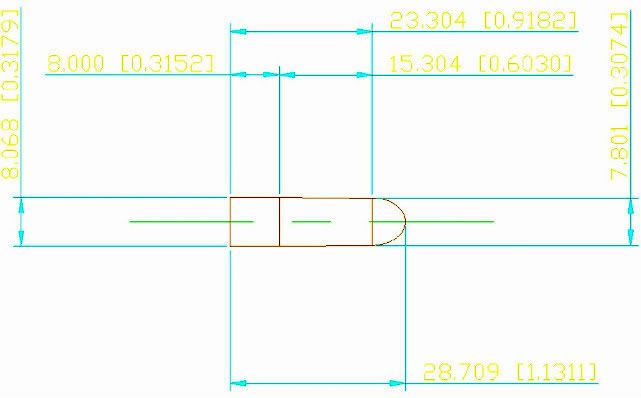

Kills turkey's dead! Patched with shaped patch.

Patched with shaped patch.

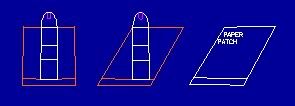

Blasphemy, I know!

Blasphemy, I know!

That's all there is to the patch tail. It works!

That's all there is to the patch tail. It works! Looks wet because it is - it was washed.

Looks wet because it is - it was washed.

No field trials yet!

No field trials yet!

Straight out the mold.

Straight out the mold.